Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 07, 2025 04:35

Back to list

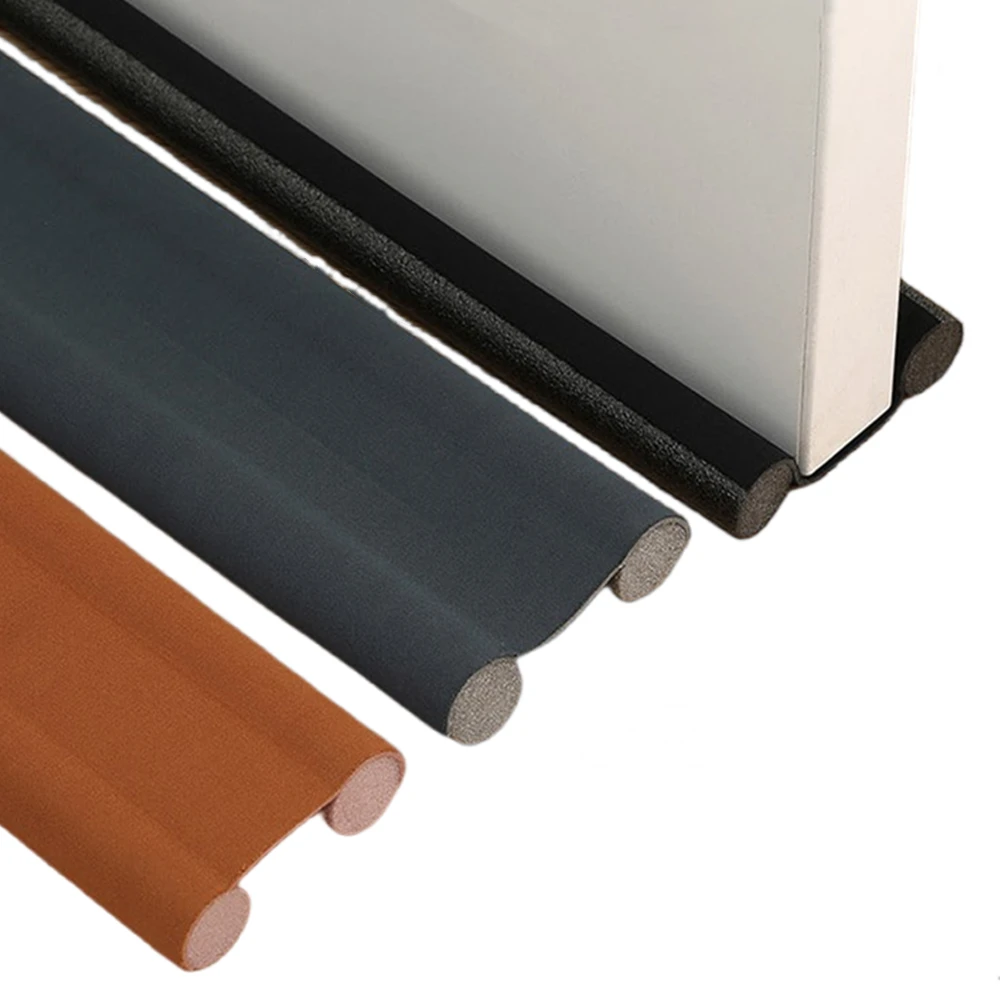

Factory Sale Industrial Black Shock Absorbing Epdm

Weather stripping adhesive is an essential component in enhancing the energy efficiency and comfort of your home, but selecting the right type requires a nuanced understanding of product specifications, application methods, and surface compatibility. This guide aims to provide a comprehensive insight into weather stripping adhesives, backed by years of experience and professional expertise.

The effectiveness of a weather stripping adhesive can also depend heavily on proper application techniques. Prior to applying, ensure that the surfaces are clean and dry. Residues from dust, oils, or old adhesives can significantly compromise adhesion, leading to premature failure. Professionals often use alcohol-based cleansers to prepare surfaces, ensuring maximal adhesion. Assessing customer reviews and expert analyses can further bolster the decision-making process when selecting an adhesive. Top-rated weather stripping adhesives often earn high marks for versatility and strong performance across a range of temperatures and humidity levels. An invaluable tip from industry experts involves applying a small amount of adhesive to test pieces of the surface materials to gauge compatibility and bonding strength before full-scale application. Trustworthy brands in the weather stripping adhesive market are those that consistently invest in product development and quality testing. Companies with a long-standing reputation in the home improvement industry often provide extensive resources, including detailed product datasheets and customer support services to assist in the selection and application process. In conclusion, the selection and application of weather stripping adhesive are critical steps in improving home energy efficiency through effective weather sealing. By considering the adhesive’s compatibility, drying time, application techniques, and brand reliability, homeowners and professionals alike can ensure they select the right product for their needs. A well-chosen adhesive not only prolongs the life of your weather stripping but also enhances the overall performance of your home’s insulation, resulting in greater energy savings and comfort.

The effectiveness of a weather stripping adhesive can also depend heavily on proper application techniques. Prior to applying, ensure that the surfaces are clean and dry. Residues from dust, oils, or old adhesives can significantly compromise adhesion, leading to premature failure. Professionals often use alcohol-based cleansers to prepare surfaces, ensuring maximal adhesion. Assessing customer reviews and expert analyses can further bolster the decision-making process when selecting an adhesive. Top-rated weather stripping adhesives often earn high marks for versatility and strong performance across a range of temperatures and humidity levels. An invaluable tip from industry experts involves applying a small amount of adhesive to test pieces of the surface materials to gauge compatibility and bonding strength before full-scale application. Trustworthy brands in the weather stripping adhesive market are those that consistently invest in product development and quality testing. Companies with a long-standing reputation in the home improvement industry often provide extensive resources, including detailed product datasheets and customer support services to assist in the selection and application process. In conclusion, the selection and application of weather stripping adhesive are critical steps in improving home energy efficiency through effective weather sealing. By considering the adhesive’s compatibility, drying time, application techniques, and brand reliability, homeowners and professionals alike can ensure they select the right product for their needs. A well-chosen adhesive not only prolongs the life of your weather stripping but also enhances the overall performance of your home’s insulation, resulting in greater energy savings and comfort.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024