Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 07, 2025 04:11

Back to list

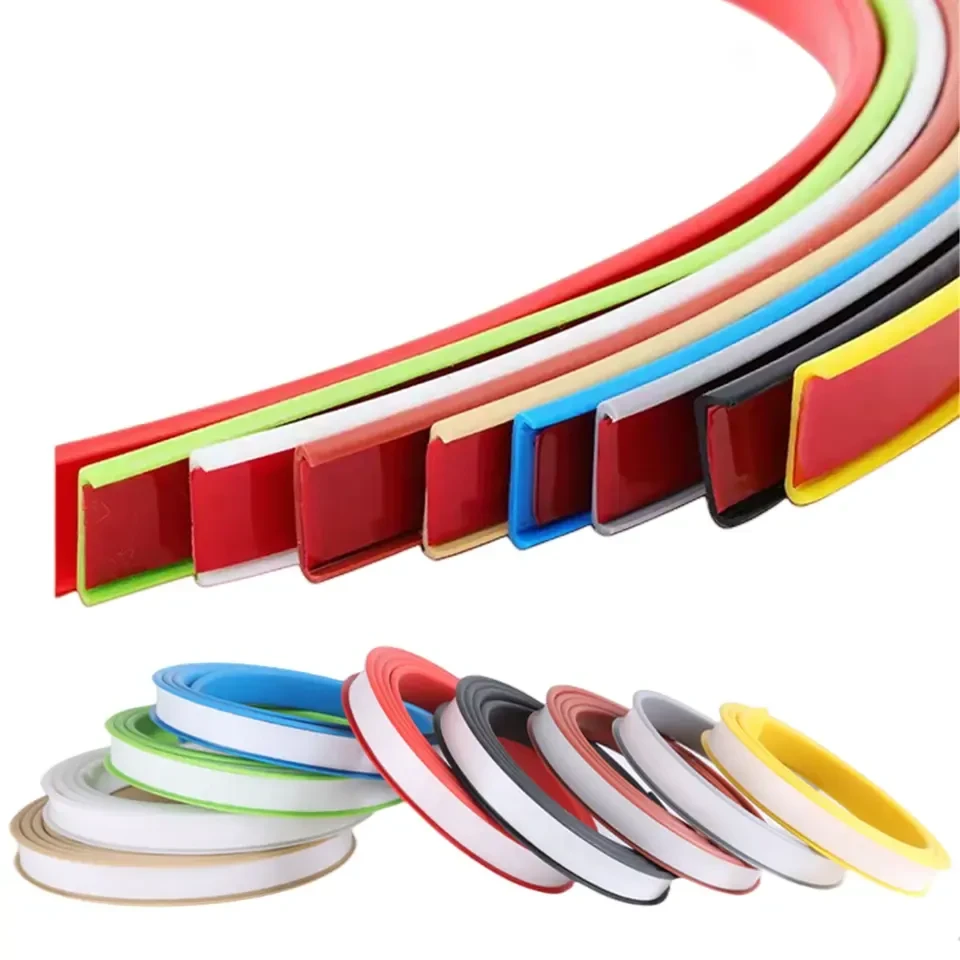

Edge Banding Tape Furniture Wood Board Cabinet Tab

When it comes to maintaining the integrity and efficiency of various types of doors, door strip rubber products often fly under the radar. Yet, their importance cannot be overstated. As an industry expert with substantial experience in door components, it's clear that these simple additions can dramatically extend the life of a door and improve a building's energy efficiency.

Moreover, door strip rubber’s efficacy in energy savings has been increasingly recognized by energy audit professionals. Buildings equipped with quality door sealing systems demonstrate a marked reduction in heating and cooling requirements. This aspect not only contributes to environmental sustainability but also aligns with modern standards for green building certifications, a burgeoning requirement across new constructions. In terms of brand authority and product trustworthiness, well-established manufacturers have been leading the way in innovation, delivering solutions that cater to both residential and commercial needs. Based on factual data and real-world application insights, the incorporation of premium door strip rubber can enhance a building's energy profile, serving as a testament to industry competence and commitment to sustainable practices. With customer awareness growing about the benefits of properly sealed buildings, as an authority in the field, I advocate for continuous research and development in the materials used for door strip rubber. Advances in technology continue to refine these products, emphasizing ease of installation, effectiveness, and durability. In conclusion, investing in quality door strip rubber is not merely about filling gaps but enhancing the overall experience of using a building—making it quieter, more energy-efficient, and sustainable. The implementation of these seals offers tangible benefits that extend well beyond their initial cost. When a qualified expert evaluates your space, the choice of the right door strip rubber not only underscores the expertise behind its selection but also reinforces the reliability often associated with superior building maintenance practices. It's a strategic decision with far-reaching impacts, promising long-term gains in both function and economics.

Moreover, door strip rubber’s efficacy in energy savings has been increasingly recognized by energy audit professionals. Buildings equipped with quality door sealing systems demonstrate a marked reduction in heating and cooling requirements. This aspect not only contributes to environmental sustainability but also aligns with modern standards for green building certifications, a burgeoning requirement across new constructions. In terms of brand authority and product trustworthiness, well-established manufacturers have been leading the way in innovation, delivering solutions that cater to both residential and commercial needs. Based on factual data and real-world application insights, the incorporation of premium door strip rubber can enhance a building's energy profile, serving as a testament to industry competence and commitment to sustainable practices. With customer awareness growing about the benefits of properly sealed buildings, as an authority in the field, I advocate for continuous research and development in the materials used for door strip rubber. Advances in technology continue to refine these products, emphasizing ease of installation, effectiveness, and durability. In conclusion, investing in quality door strip rubber is not merely about filling gaps but enhancing the overall experience of using a building—making it quieter, more energy-efficient, and sustainable. The implementation of these seals offers tangible benefits that extend well beyond their initial cost. When a qualified expert evaluates your space, the choice of the right door strip rubber not only underscores the expertise behind its selection but also reinforces the reliability often associated with superior building maintenance practices. It's a strategic decision with far-reaching impacts, promising long-term gains in both function and economics.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024