Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 13, 2025 11:07

Back to list

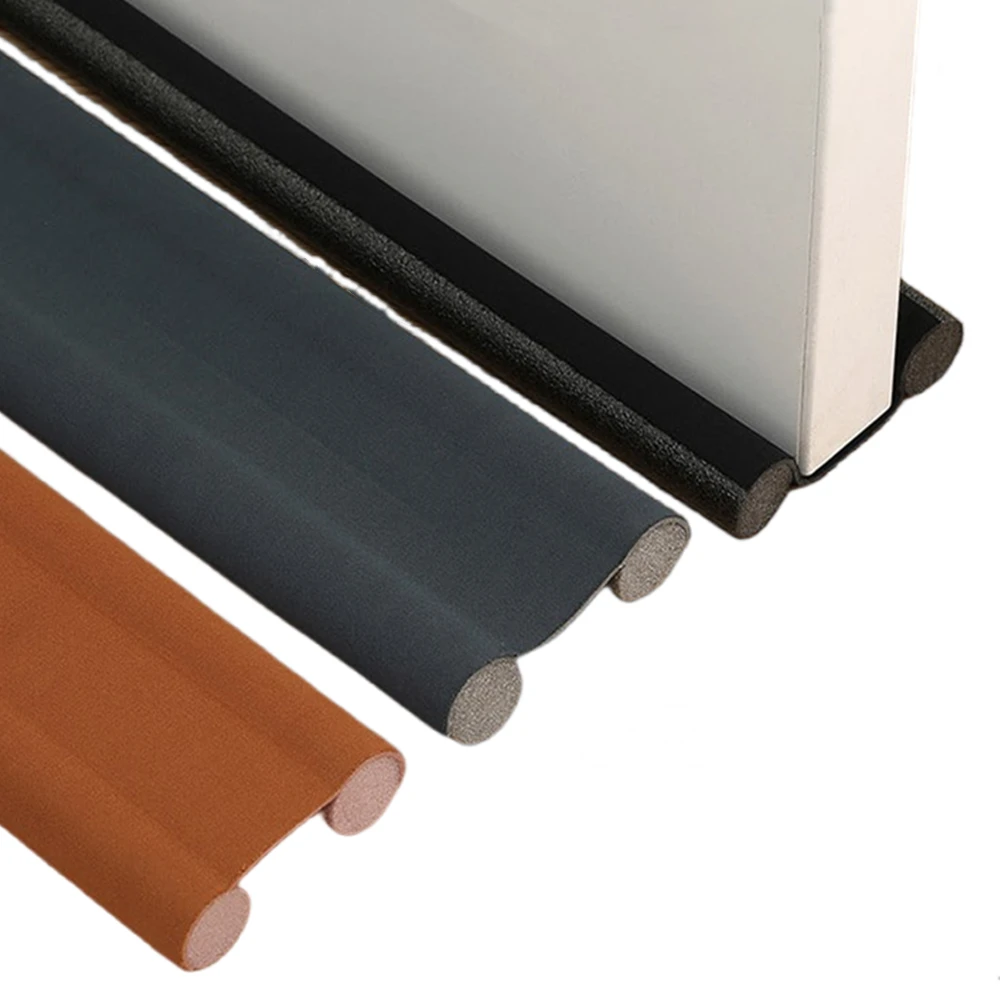

t rubber strip

Navigating the world of rubber strips can be challenging without the right expertise. Understanding the diverse applications and nuances of these versatile products ensures not only proper utilization but also maximizes efficiency across various industries.

Authoritative insight within the industry often highlights the need for customizable rubber strip solutions. Manufacturers now offer bespoke options that cater to specific business needs. For example, food-grade rubber strips that meet stringent safety standards are essential for industries like food processing and pharmaceuticals, where contamination control is critical. These industry-specific solutions underscore the importance of understanding and selecting the appropriate rubber strip to avoid costly inefficiencies and safety hazards. Trustworthiness in the rubber strip sector is built on several pillars—product integrity, compliance with industry standards, and reliable customer service. Companies striving to be leaders in this niche must earn customer trust by consistently delivering products that meet rigorous quality checks and adhere to international standards. Certifications from recognized bodies are essential in demonstrating compliance and boosting consumer confidence. It is also worth noting the technological advancements in rubber strip production. Continuous research and development have led to improved properties such as increased temperature resistance and enhanced durability. For customers navigating the selection process, partnering with manufacturers that invest in innovation provides a winning edge. Such partnerships ensure access to cutting-edge solutions that keep pace with evolving industry demands and environmental considerations. In conclusion, rubber strips are more than mere ancillary components; they are fundamental to the operational success of many products and systems. Their multifaceted applications span across industries, offering solutions to common challenges such as environmental sealing, insulation, and protection against external elements. For businesses and individuals alike, understanding the importance of selecting the right rubber strip—tailored to specific needs—cannot be overstated. Hence, engaging with experienced suppliers who are committed to quality and innovation will invariably lead to enhanced product performance and customer satisfaction, paving the way for long-term success.

Authoritative insight within the industry often highlights the need for customizable rubber strip solutions. Manufacturers now offer bespoke options that cater to specific business needs. For example, food-grade rubber strips that meet stringent safety standards are essential for industries like food processing and pharmaceuticals, where contamination control is critical. These industry-specific solutions underscore the importance of understanding and selecting the appropriate rubber strip to avoid costly inefficiencies and safety hazards. Trustworthiness in the rubber strip sector is built on several pillars—product integrity, compliance with industry standards, and reliable customer service. Companies striving to be leaders in this niche must earn customer trust by consistently delivering products that meet rigorous quality checks and adhere to international standards. Certifications from recognized bodies are essential in demonstrating compliance and boosting consumer confidence. It is also worth noting the technological advancements in rubber strip production. Continuous research and development have led to improved properties such as increased temperature resistance and enhanced durability. For customers navigating the selection process, partnering with manufacturers that invest in innovation provides a winning edge. Such partnerships ensure access to cutting-edge solutions that keep pace with evolving industry demands and environmental considerations. In conclusion, rubber strips are more than mere ancillary components; they are fundamental to the operational success of many products and systems. Their multifaceted applications span across industries, offering solutions to common challenges such as environmental sealing, insulation, and protection against external elements. For businesses and individuals alike, understanding the importance of selecting the right rubber strip—tailored to specific needs—cannot be overstated. Hence, engaging with experienced suppliers who are committed to quality and innovation will invariably lead to enhanced product performance and customer satisfaction, paving the way for long-term success.

Next:

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024