Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 15, 2025 10:49

Back to list

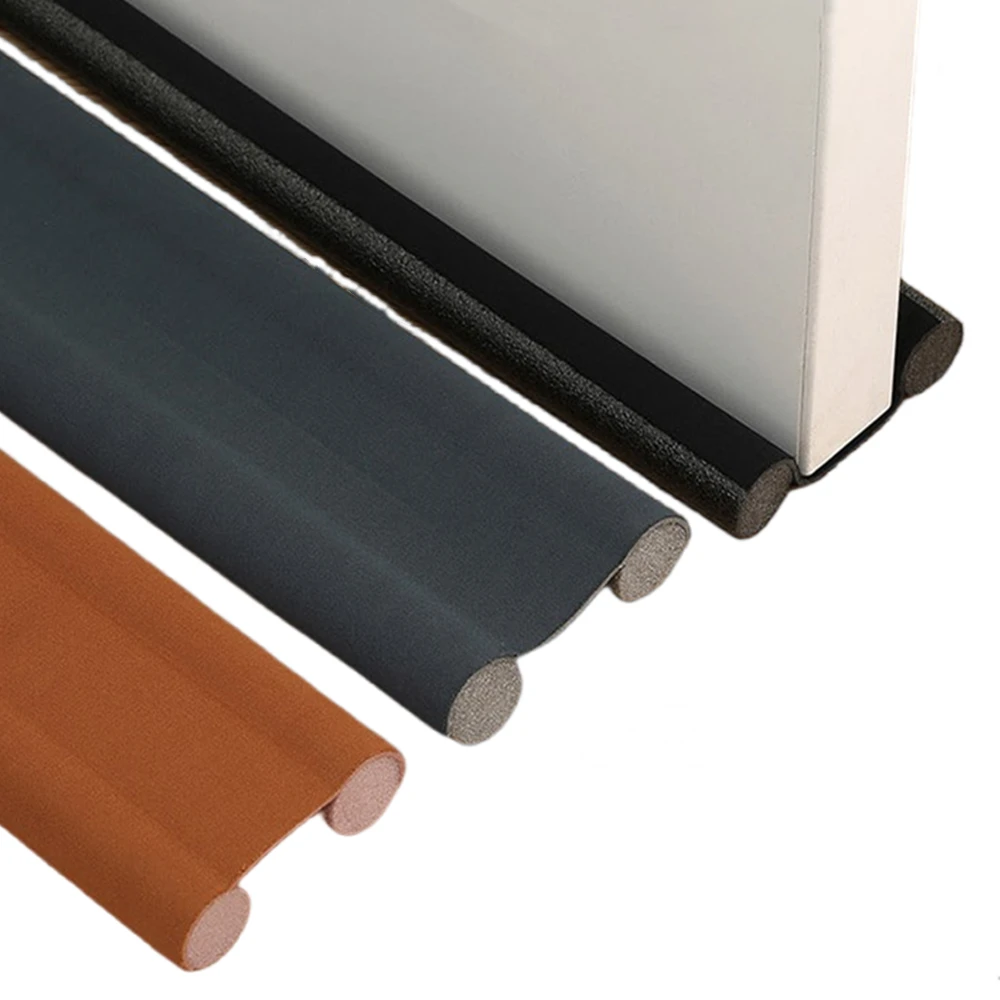

thin rubber seal strip

Utilizing a thin rubber seal strip can make a remarkable difference in enhancing the durability, efficiency, and safety of numerous applications. These versatile strips are pivotal for creating strong seals in a multitude of industries such as automotive, marine, construction, and consumer goods. Their popularity is ever-increasing due to their ability to prevent leakage, reduce noise, and improve insulation, making them indispensable across various domains.

Product customization plays an essential role in the operational effectiveness of rubber seal strips. Manufacturers often provide strips in various shapes, including D, P, and bulb profiles, each suitable for distinct applications. Additionally, adhesive-backed options increase ease of installation and provide a hassle-free sealing experience, especially in scenarios where mechanical fastening is impractical. The widespread application of thin rubber seal strips does not negate the importance of ongoing technological advancements and innovations within the industry. Recent developments have included incorporating antimicrobial properties into seal strips for applications in healthcare and food industries, where maintaining sterile environments is crucial. These innovations further illustrate the versatile and dynamic nature of rubber seal strips, catering to evolving industry standards and consumer expectations. As with any industrial product, the credibility and trustworthiness of the supplier are paramount. Working with reputable manufacturers ensures the highest quality materials are used, which translates to enhanced performance and durability. Suppliers with extensive expertise and experience in producing rubber seal strips are more likely to offer superior products backed by testing and certification, reducing the risk of premature failure and ensuring safety. In summary, the integration of thin rubber seal strips into any application is a testament to their indispensable nature in providing efficient, effective, and resilient sealing solutions. Their versatility across diverse industries, combined with ongoing innovations and customization options, ensures they will remain a critical component within engineering and consumer products worldwide. Selecting the appropriate type and working with a reputable supplier will maximize performance and satisfaction, underscoring the importance of informed decision-making in the use of rubber seal strips.

Product customization plays an essential role in the operational effectiveness of rubber seal strips. Manufacturers often provide strips in various shapes, including D, P, and bulb profiles, each suitable for distinct applications. Additionally, adhesive-backed options increase ease of installation and provide a hassle-free sealing experience, especially in scenarios where mechanical fastening is impractical. The widespread application of thin rubber seal strips does not negate the importance of ongoing technological advancements and innovations within the industry. Recent developments have included incorporating antimicrobial properties into seal strips for applications in healthcare and food industries, where maintaining sterile environments is crucial. These innovations further illustrate the versatile and dynamic nature of rubber seal strips, catering to evolving industry standards and consumer expectations. As with any industrial product, the credibility and trustworthiness of the supplier are paramount. Working with reputable manufacturers ensures the highest quality materials are used, which translates to enhanced performance and durability. Suppliers with extensive expertise and experience in producing rubber seal strips are more likely to offer superior products backed by testing and certification, reducing the risk of premature failure and ensuring safety. In summary, the integration of thin rubber seal strips into any application is a testament to their indispensable nature in providing efficient, effective, and resilient sealing solutions. Their versatility across diverse industries, combined with ongoing innovations and customization options, ensures they will remain a critical component within engineering and consumer products worldwide. Selecting the appropriate type and working with a reputable supplier will maximize performance and satisfaction, underscoring the importance of informed decision-making in the use of rubber seal strips.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024