Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 17, 2025 12:35

Back to list

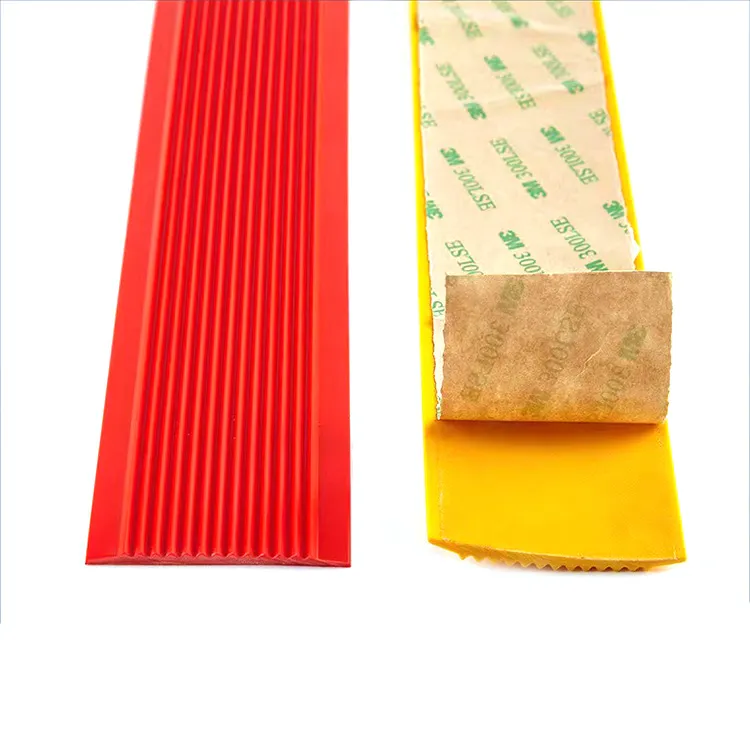

Baby proofing edge corner protector 2m soft rubber

Silicone weather stripping for doors stands as an essential product in maintaining an energy-efficient and comfortable living environment. Crafted from high-quality silicone, this material outshines its counterparts in durability and performance. Here, we delve into the intricacies of silicone weather stripping for doors, highlighting its benefits, installation tips, and long-term efficacy.

In terms of authenticity, silicone weather stripping for doors complies with various industry standards—an assurance that it offers recognized levels of performance and safety. Brands offering certified products often undergo rigorous testing to meet regulations, adding a layer of trust for consumers seeking reliable solutions. Endorsements or certifications from industry bodies can further cement a product's credibility in the eyes of discerning buyers. Tailored maintenance is recommended to prolong the life span of weather stripping. Regular inspections for damages or signs of wear and tear can prevent inefficiencies from arising. Cleaning the strips with a mild detergent prevents dirt accumulation and ensures a firm adherence to the door surface. When issues are detected early, replacing or readjusting weather strips can be a simple, cost-effective task, rather than facing inflated energy bills or the discomfort of drafts. Finally, silicone weather stripping for doors offers a perfect blend of innovation and practicality. As homeowners or business operators, investing in high-quality weather sealing solutions can transform living or workspaces into comfortable, energy-efficient environments. In the pursuit of expertise in home improvement, understanding these nuanced benefits not only empowers purchasing decisions but also reinforces the commitment to sustainability and comfort. By embracing silicone weather stripping, users are not only equipping themselves with a product that embodies longevity and resilience but one that also meets contemporary demands for energy efficiency and ecological stewardship.

In terms of authenticity, silicone weather stripping for doors complies with various industry standards—an assurance that it offers recognized levels of performance and safety. Brands offering certified products often undergo rigorous testing to meet regulations, adding a layer of trust for consumers seeking reliable solutions. Endorsements or certifications from industry bodies can further cement a product's credibility in the eyes of discerning buyers. Tailored maintenance is recommended to prolong the life span of weather stripping. Regular inspections for damages or signs of wear and tear can prevent inefficiencies from arising. Cleaning the strips with a mild detergent prevents dirt accumulation and ensures a firm adherence to the door surface. When issues are detected early, replacing or readjusting weather strips can be a simple, cost-effective task, rather than facing inflated energy bills or the discomfort of drafts. Finally, silicone weather stripping for doors offers a perfect blend of innovation and practicality. As homeowners or business operators, investing in high-quality weather sealing solutions can transform living or workspaces into comfortable, energy-efficient environments. In the pursuit of expertise in home improvement, understanding these nuanced benefits not only empowers purchasing decisions but also reinforces the commitment to sustainability and comfort. By embracing silicone weather stripping, users are not only equipping themselves with a product that embodies longevity and resilience but one that also meets contemporary demands for energy efficiency and ecological stewardship.

Next:

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024