Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 13, 2025 17:17

Back to list

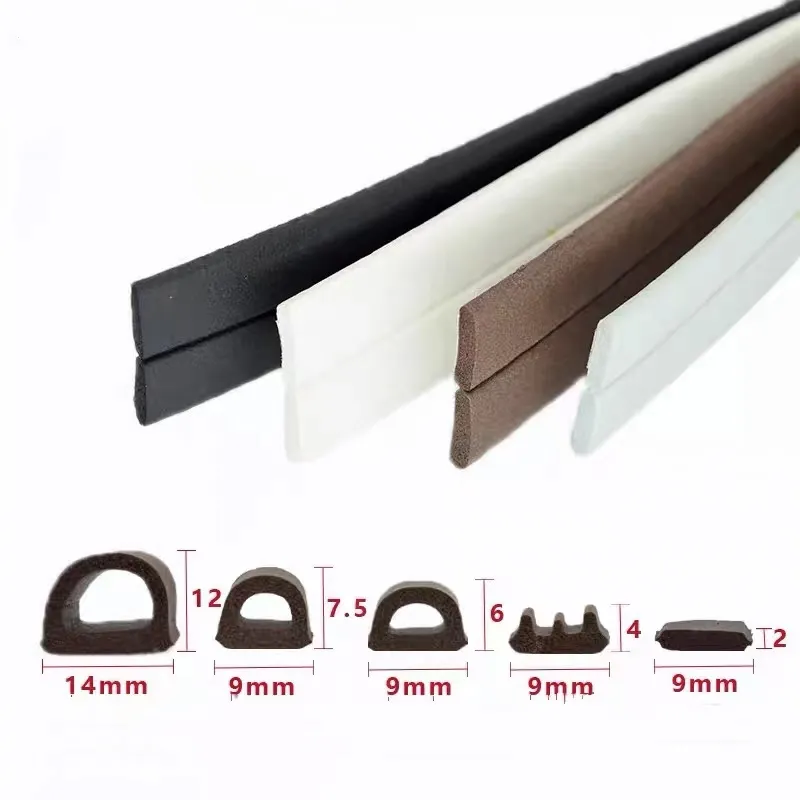

Edge Banding Tape Furniture Wood Board Cabinet Tab

Rubber strips have become an indispensable component in the automotive industry, offering a myriad of benefits that enhance the performance, durability, and safety of vehicles. These versatile materials serve numerous purposes within a car, from sealing elements to cushioning and more, making them crucial for optimal vehicle function.

Trustworthiness in rubber strip products is established through rigorous testing and compliance with international standards. Manufacturers invest heavily in research and development to innovate and improve rubber formulations and production techniques. This dedication not only ensures product reliability but also longevity, as high-quality rubber strips can withstand extensive use without significant degradation. For consumers, recognizing brands that adhere to these high standards provides reassurance of the product’s trustworthiness. One noteworthy development in the field of automotive rubber strips is the integration of eco-friendly materials. With the industry’s increasing shift towards sustainability, researchers are developing rubber compounds that are recyclable and biodegradable without compromising on performance. This not only aligns with global environmental goals but also meets the growing consumer demand for sustainable automotive solutions. For automotive professionals and hobbyists alike, understanding the application and maintenance of rubber strips can greatly influence the overall vehicle health. Regular inspections for wear and tear, especially in high-friction areas or under extreme environmental conditions, can preempt potential issues. Replacement is recommended if the rubber shows signs of cracking, hardening, or other forms of deterioration. In-depth knowledge and expertise in handling these components ensure that a vehicle remains in top working condition, providing safety and comfort to its occupants. In summary, rubber strips in cars are essential yet often overlooked components that require a nuanced understanding of their benefits and applications. Through expert engineering, authoritative testing, and growing innovations in sustainability, these products continue to evolve, providing enhanced experiences for drivers globally. Whether it's dampening vibrations, sealing out elements, or contributing to eco-friendly initiatives, rubber strips undeniably play a pivotal role in the automotive landscape. By prioritizing high-quality materials and regular maintenance, car owners can maximize the efficiency and reliability of these crucial components, ensuring their vehicle remains a steadfast companion on the road.

Trustworthiness in rubber strip products is established through rigorous testing and compliance with international standards. Manufacturers invest heavily in research and development to innovate and improve rubber formulations and production techniques. This dedication not only ensures product reliability but also longevity, as high-quality rubber strips can withstand extensive use without significant degradation. For consumers, recognizing brands that adhere to these high standards provides reassurance of the product’s trustworthiness. One noteworthy development in the field of automotive rubber strips is the integration of eco-friendly materials. With the industry’s increasing shift towards sustainability, researchers are developing rubber compounds that are recyclable and biodegradable without compromising on performance. This not only aligns with global environmental goals but also meets the growing consumer demand for sustainable automotive solutions. For automotive professionals and hobbyists alike, understanding the application and maintenance of rubber strips can greatly influence the overall vehicle health. Regular inspections for wear and tear, especially in high-friction areas or under extreme environmental conditions, can preempt potential issues. Replacement is recommended if the rubber shows signs of cracking, hardening, or other forms of deterioration. In-depth knowledge and expertise in handling these components ensure that a vehicle remains in top working condition, providing safety and comfort to its occupants. In summary, rubber strips in cars are essential yet often overlooked components that require a nuanced understanding of their benefits and applications. Through expert engineering, authoritative testing, and growing innovations in sustainability, these products continue to evolve, providing enhanced experiences for drivers globally. Whether it's dampening vibrations, sealing out elements, or contributing to eco-friendly initiatives, rubber strips undeniably play a pivotal role in the automotive landscape. By prioritizing high-quality materials and regular maintenance, car owners can maximize the efficiency and reliability of these crucial components, ensuring their vehicle remains a steadfast companion on the road.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024