Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 15, 2025 03:54

Back to list

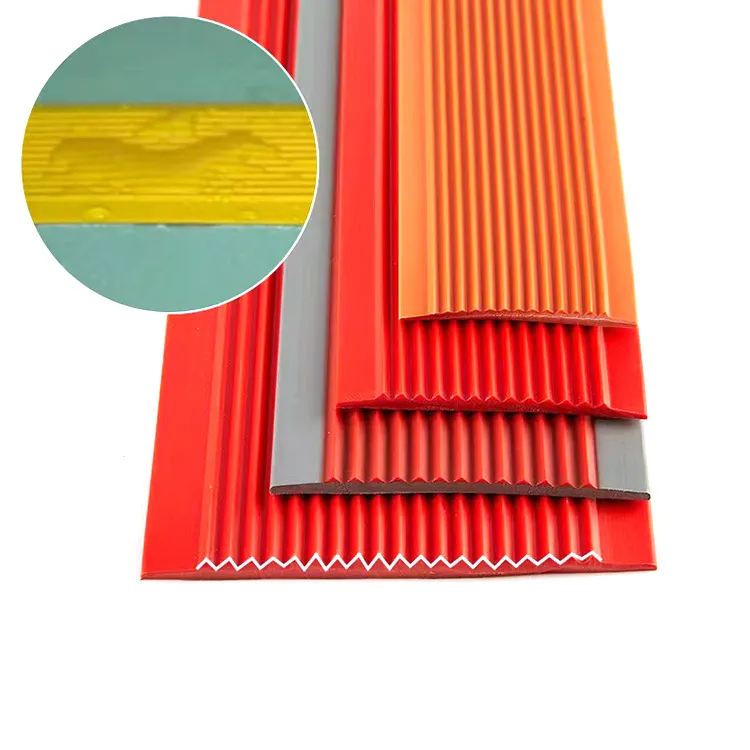

rubber glazing bead

Rubber glazing beads play a pivotal role in enhancing the durability and aesthetic appeal of windows and doors, providing a secure seal between glass and frame. These versatile components have garnered attention for their remarkable ability to resist environmental elements, ensuring longevity and efficiency. With years of field expertise, professionals understand that selecting the right glazing bead is crucial for both performance and appearance.

The authority of rubber glazing beads in the construction industry is further solidified by their compliance with rigorous safety and performance standards. These components undergo stringent testing to ensure they meet or exceed industry benchmarks for air and water tightness, wind resistance, and durability. Such compliance is not merely a suggestion but a necessity for builders looking to satisfy building codes and ensure occupant safety. Trust is an essential component when it comes to choosing the right materials for construction. Manufacturers of rubber glazing beads invest heavily in research and development to advance the technology behind these products. This commitment to innovation not only enhances product performance but also reinforces consumer confidence. End users can trust that these products are the result of meticulous engineering designed to meet the highest standards of quality and durability. In sum, rubber glazing beads are not just an ancillary component but a cornerstone of effective and aesthetically pleasing window and door installations. Their ability to enhance energy efficiency, coupled with their broad design adaptability and compliance with safety norms, makes them an indispensable choice for modern construction needs. Industry professionals who seek to deliver superior performance and elegance in their construction projects will find rubber glazing beads an irreplaceable element in their toolkit. The sustained trust in rubber glazing beads is not solely based on their performance but also on the unrivaled expertise of the companies that produce them. With continual advancements and an uncompromising approach to quality, these manufacturers maintain their authority in the market, making rubber glazing beads a preferred choice for construction projects that demand the best in both function and form. As the requirements of architectural design and sustainability continue to evolve, rubber glazing beads will likely lead the charge, setting new standards for excellence in construction materials.

The authority of rubber glazing beads in the construction industry is further solidified by their compliance with rigorous safety and performance standards. These components undergo stringent testing to ensure they meet or exceed industry benchmarks for air and water tightness, wind resistance, and durability. Such compliance is not merely a suggestion but a necessity for builders looking to satisfy building codes and ensure occupant safety. Trust is an essential component when it comes to choosing the right materials for construction. Manufacturers of rubber glazing beads invest heavily in research and development to advance the technology behind these products. This commitment to innovation not only enhances product performance but also reinforces consumer confidence. End users can trust that these products are the result of meticulous engineering designed to meet the highest standards of quality and durability. In sum, rubber glazing beads are not just an ancillary component but a cornerstone of effective and aesthetically pleasing window and door installations. Their ability to enhance energy efficiency, coupled with their broad design adaptability and compliance with safety norms, makes them an indispensable choice for modern construction needs. Industry professionals who seek to deliver superior performance and elegance in their construction projects will find rubber glazing beads an irreplaceable element in their toolkit. The sustained trust in rubber glazing beads is not solely based on their performance but also on the unrivaled expertise of the companies that produce them. With continual advancements and an uncompromising approach to quality, these manufacturers maintain their authority in the market, making rubber glazing beads a preferred choice for construction projects that demand the best in both function and form. As the requirements of architectural design and sustainability continue to evolve, rubber glazing beads will likely lead the charge, setting new standards for excellence in construction materials.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024