rubber gasket strip

The Essential Role of Rubber Gasket Strips in Modern Industries

Rubber gasket strips are indispensable components in a wide array of industrial applications. Their primary function is to create a seal between two surfaces, preventing the escape of fluids, gases, and debris. This functionality is critical in various sectors, including automotive, aerospace, construction, and food processing. The versatility and adaptability of rubber gaskets make them a popular choice across numerous applications, ensuring safety, efficiency, and reliability.

One of the most significant advantages of rubber gasket strips is their ability to conform to irregular surfaces. Unlike rigid materials, rubber can compress and expand, enabling it to fill gaps and voids effectively. This characteristic is particularly valuable in environments where equipment undergoes constant movement or vibration. By maintaining a tight seal even under these conditions, rubber gaskets help prevent leaks that could lead to operational inefficiencies or hazardous situations.

In automotive and aerospace industries, sealed components are critical for functionality and safety. Engines, fuel tanks, and hydraulic systems rely heavily on rubber gasket strips to prevent leaks that could cause catastrophic failures. For instance, a malfunctioning gasket in an engine could lead to coolant leaks, resulting in overheating and potential engine damage. The reliability of rubber gaskets is therefore paramount; they are rigorously tested to withstand extreme temperatures, pressures, and chemicals encountered in these environments.

Another vital sector where rubber gasket strips are essential is in the food and beverage industry. Here, cleanliness and hygiene standards are paramount. Rubber gaskets must not only provide an effective seal but also meet strict regulatory guidelines to ensure they do not contaminate products. Food-grade rubber gaskets are manufactured from materials that are safe for food contact, providing peace of mind to manufacturers and consumers alike. They play a crucial role in processing equipment, ensuring that products maintain their quality and safety from production to packaging.

rubber gasket strip

Moreover, rubber gasket strips are customizable to fit various shapes, sizes, and applications. Manufacturers can produce gaskets in numerous profiles and thicknesses, allowing businesses to select the ideal solution for their specific needs. Advanced manufacturing techniques, such as extrusion and molding, enable the creation of gaskets that can withstand particular environmental conditions, such as UV exposure or chemical corrosion.

Durability is another vital feature of rubber gasket strips. They typically exhibit excellent resistance to aging, weathering, and degradation from exposure to oils and chemicals. This longevity reduces the need for frequent replacements, resulting in cost savings for businesses over time. Companies that invest in high-quality rubber gaskets often find that they can significantly reduce maintenance costs and increase the lifespan of their equipment.

Sustainability is becoming increasingly important in modern manufacturing processes. As industries strive to become more eco-friendly, many are turning to sustainable rubber options, such as recycled materials or bio-based rubbers. These environmentally friendly gaskets maintain the performance characteristics that industries require while also reducing the environmental footprint of manufacturing processes.

In conclusion, rubber gasket strips are vital components across a multitude of industries, playing a key role in ensuring safety, efficiency, and sustainability. Their adaptability, durability, and ability to provide effective sealing solutions make them an essential choice for various applications. As technology advances and industries evolve, the importance of high-quality rubber gaskets will only continue to grow, supporting the operational integrity and longevity of machinery and systems worldwide.

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

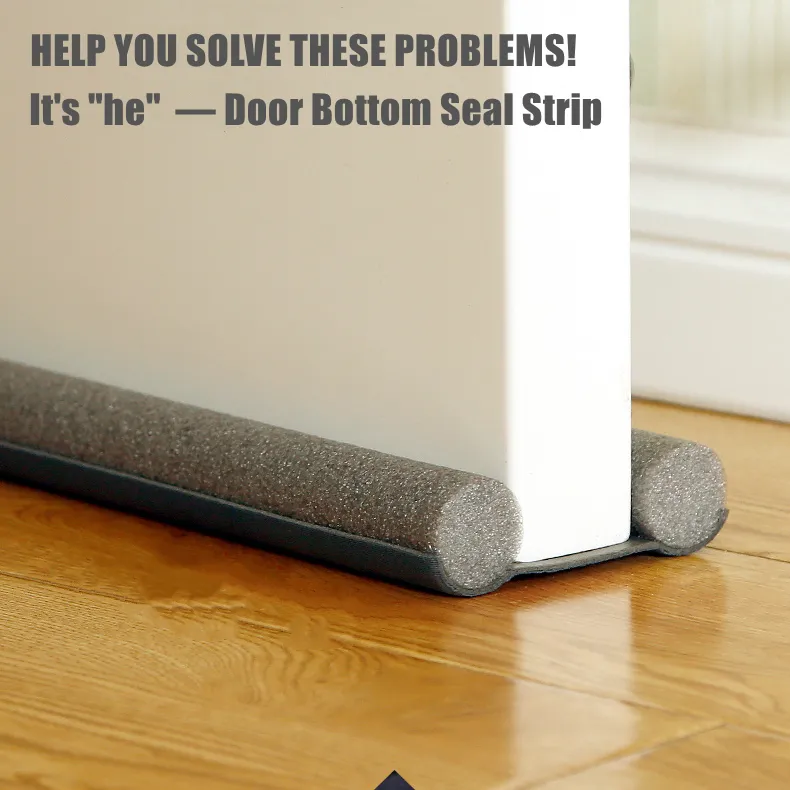

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024