Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 12, 2025 01:57

Back to list

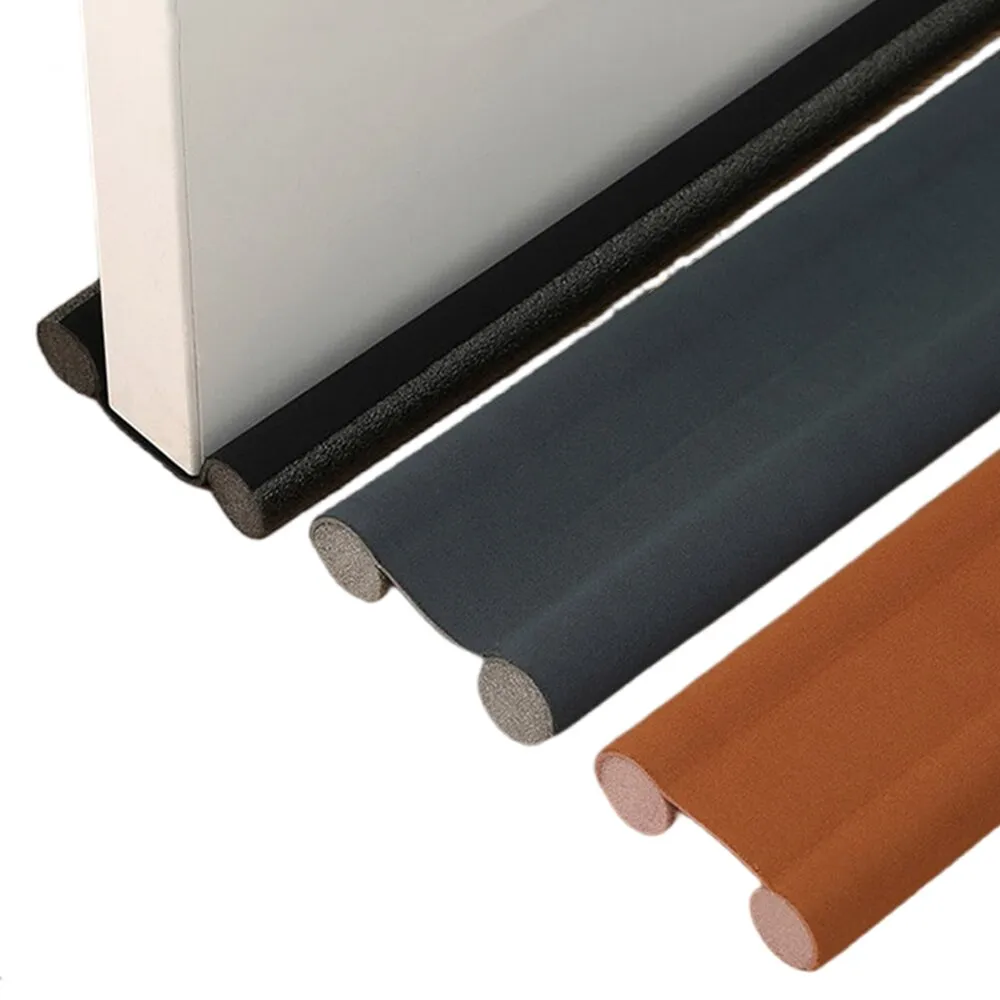

rubber gasket seal strip

Rubber gasket seal strips stand at the forefront of industrial solutions, optimizing both sealing efficiency and longevity across multiple applications. These seal strips, integral to numerous industries, present an innovative blend of material science and engineering prowess, warranting attention through their unparalleled effectiveness and adaptability.

Authoritativeness in assessing the quality and application of rubber gasket seal strips is crucial. Industry standards such as ASTM and ISO provide benchmarks that ensure these products meet stringent quality requisites. Manufacturers often perform rigorous testing to certify that their products comply with these standards, establishing a tier of reliability and performance assurance. Trustworthiness is earned through consistent, reliable performance, evidenced by numerous case studies and testimonials across varied industries. In HVAC systems, for example, rubber gasket seal strips have proven their worth by significantly reducing air leaks, thereby enhancing energy efficiency and reducing operational costs. Such testimonials from industry leaders fortify trust, underscoring these products' effectiveness across diverse environments. Furthermore, the environmental benefits of these seal strips cannot be overstated. Many rubber gasket seal strips are designed with sustainability in mind, utilizing recyclable materials in their production. This commitment not only lessens environmental impact but also aligns with the increasing demand for sustainable industrial practices. In conclusion, rubber gasket seal strips are indispensable to industries seeking reliability and efficiency in sealing solutions. Their advanced material properties, coupled with robust performance metrics, affirm their status as a top choice for engineers and industry professionals. As industries continue to evolve, the demand for such adaptive and proven technologies is certain to rise, confirming the ongoing relevance and necessity of rubber gasket seal strips in meeting complex industrial challenges.

Authoritativeness in assessing the quality and application of rubber gasket seal strips is crucial. Industry standards such as ASTM and ISO provide benchmarks that ensure these products meet stringent quality requisites. Manufacturers often perform rigorous testing to certify that their products comply with these standards, establishing a tier of reliability and performance assurance. Trustworthiness is earned through consistent, reliable performance, evidenced by numerous case studies and testimonials across varied industries. In HVAC systems, for example, rubber gasket seal strips have proven their worth by significantly reducing air leaks, thereby enhancing energy efficiency and reducing operational costs. Such testimonials from industry leaders fortify trust, underscoring these products' effectiveness across diverse environments. Furthermore, the environmental benefits of these seal strips cannot be overstated. Many rubber gasket seal strips are designed with sustainability in mind, utilizing recyclable materials in their production. This commitment not only lessens environmental impact but also aligns with the increasing demand for sustainable industrial practices. In conclusion, rubber gasket seal strips are indispensable to industries seeking reliability and efficiency in sealing solutions. Their advanced material properties, coupled with robust performance metrics, affirm their status as a top choice for engineers and industry professionals. As industries continue to evolve, the demand for such adaptive and proven technologies is certain to rise, confirming the ongoing relevance and necessity of rubber gasket seal strips in meeting complex industrial challenges.

Next:

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024