Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 20, 2025 12:32

Back to list

High Density Light Truck Bed Rubber Mat 4mm 141.5×205cm C type

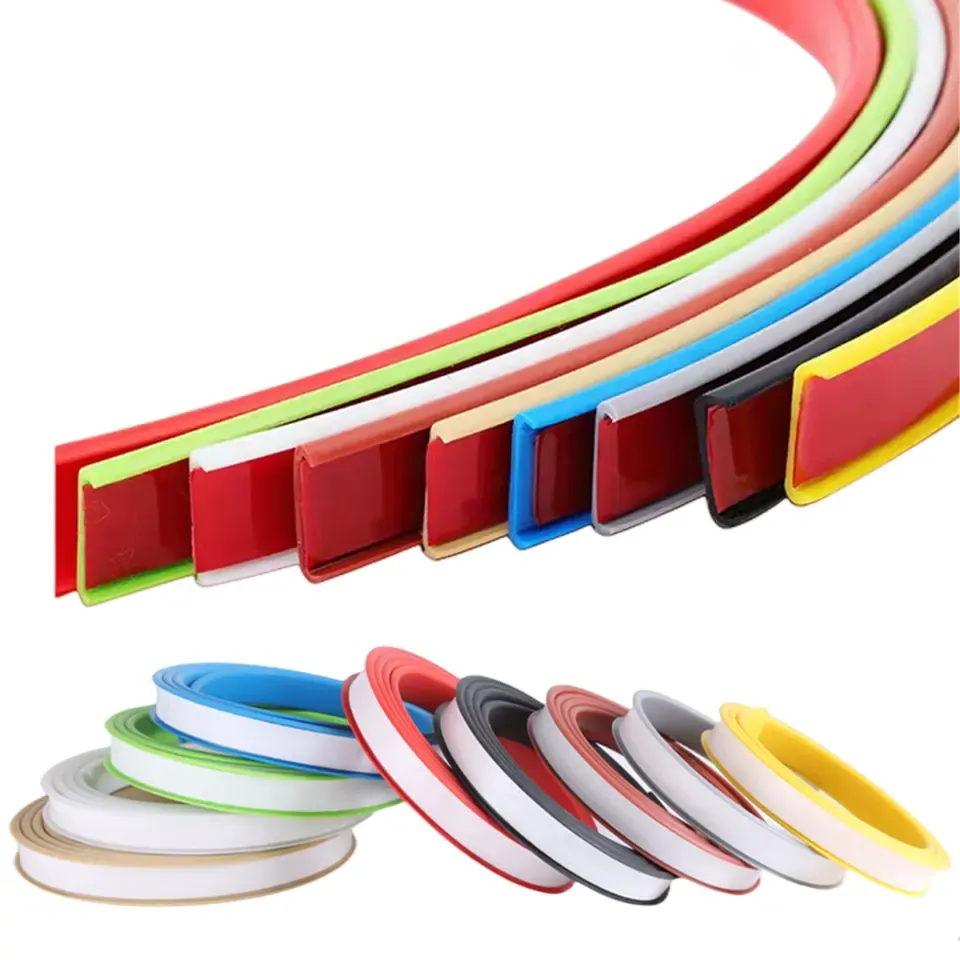

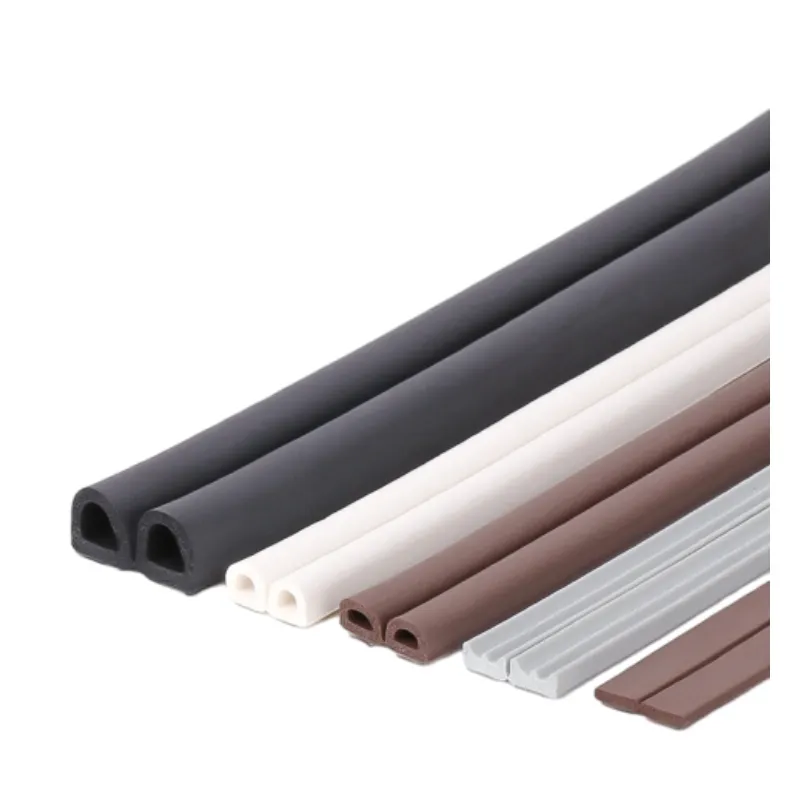

Rubber corners have reinvented the design dynamics across various industries, providing not only aesthetic appeal but also functionally critical solutions in product safety and durability. This unique material is gaining traction for its versatile features and its key role in enhancing product longevity and consumer satisfaction.

In terms of Authoritativeness, the use of rubber corners is endorsed by numerous industry standards and certifications. Leading manufacturers operate under ISO and ASTM guidelines, ensuring that their products meet global quality benchmarks. These certifications provide an authoritative validation of the product’s safety and efficacy, reassuring consumers of its high standard across various markets. Furthermore, studies and reports from independent testing organizations often cite rubber corners for their resilience and protective qualities, lending further weight to their reputation as a preferred choice among safety and design professionals. When discussing Trustworthiness, it's imperative to consider the long-term implications of rubber corners in terms of environmental impact. Reputable manufacturers focus on sustainability, employing eco-friendly processes and non-toxic materials to produce these products. The integration of recycled materials without compromising structural integrity is a tangible demonstration of these companies' commitment to environmental responsibility. Moreover, the durability of rubber corners reduces the need for frequent replacements, which contributes to waste reduction and underscores their value proposition as a sustainable choice for eco-conscious consumers. In conclusion, rubber corners exemplify a product category where experience, expertise, authoritativeness, and trustworthiness converge to deliver exceptional value. A closer market analysis shows that the continual advancement in material science and manufacturing techniques heralds an era where the predominance of rubber corners in design and safety applications will only become more pronounced. From preventing injuries and enhancing tactile experiences to providing trusted solutions across industries, rubber corners stand at the forefront of functional and innovative design, meeting and exceeding expectations in practical applications worldwide. As they continue to evolve with technological advancements, their role in shaping safer, more efficient environments remains indispensably crucial.

In terms of Authoritativeness, the use of rubber corners is endorsed by numerous industry standards and certifications. Leading manufacturers operate under ISO and ASTM guidelines, ensuring that their products meet global quality benchmarks. These certifications provide an authoritative validation of the product’s safety and efficacy, reassuring consumers of its high standard across various markets. Furthermore, studies and reports from independent testing organizations often cite rubber corners for their resilience and protective qualities, lending further weight to their reputation as a preferred choice among safety and design professionals. When discussing Trustworthiness, it's imperative to consider the long-term implications of rubber corners in terms of environmental impact. Reputable manufacturers focus on sustainability, employing eco-friendly processes and non-toxic materials to produce these products. The integration of recycled materials without compromising structural integrity is a tangible demonstration of these companies' commitment to environmental responsibility. Moreover, the durability of rubber corners reduces the need for frequent replacements, which contributes to waste reduction and underscores their value proposition as a sustainable choice for eco-conscious consumers. In conclusion, rubber corners exemplify a product category where experience, expertise, authoritativeness, and trustworthiness converge to deliver exceptional value. A closer market analysis shows that the continual advancement in material science and manufacturing techniques heralds an era where the predominance of rubber corners in design and safety applications will only become more pronounced. From preventing injuries and enhancing tactile experiences to providing trusted solutions across industries, rubber corners stand at the forefront of functional and innovative design, meeting and exceeding expectations in practical applications worldwide. As they continue to evolve with technological advancements, their role in shaping safer, more efficient environments remains indispensably crucial.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024