Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 16, 2025 00:46

Back to list

Factory Sale Industrial Black Shock Absorbing Epdm

The oven door insulation strip might seem like a minor component of your kitchen appliance, but its role is anything but trivial. Serving as a guardian against heat loss and energy inefficiency, this small yet mighty strip ensures your oven maintains the correct temperature while safeguarding your kitchen from unnecessary heat. This article unpacks the intricacies of oven door insulation strips, providing insights into why they are indispensable in modern kitchen appliances.

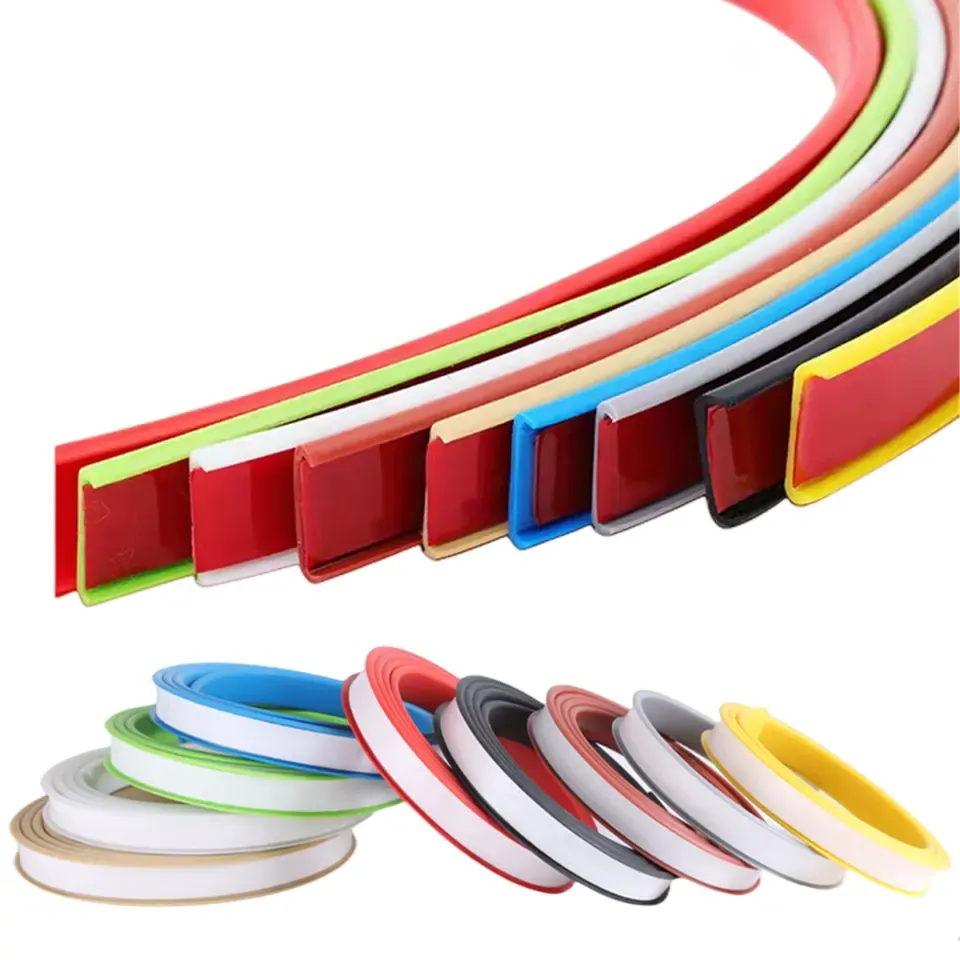

Trustworthiness Through Brand and Quality Choosing insulation strips from reputable manufacturers can make a significant difference. Brands that are specifically known for their quality assurance and rigorous testing standards offer products designed to meet or exceed industry norms. When selecting replacement strips, it is crucial to consider those that guarantee longevity, resistance to wear, and compliance with safety standards. Opting for certified products ensures you receive components that have been scrutinized for both safety and performance. Consumer Experience and Recommendations User reviews and feedback often provide invaluable insights into the practical aspects of oven door insulation strips. Many consumers recommend performing a simple dollar bill test to check the seal integrity. If a bill slides out easily when the door is closed, it might signal the need for a new strip. Moreover, sharing personal testimonials about energy savings and cooking improvements post-replacement can help reinforce the importance of this often-overlooked kitchen component. In Conclusion The oven door insulation strip plays a pivotal role in maintaining an efficient, safe, and effective cooking environment. From material selection to installation and maintenance, each step demands careful consideration. By prioritizing quality and proper upkeep, homeowners not only enhance their cooking experience but also contribute to energy conservation. The significance of this small piece of material extends far beyond the oven, touching upon broader themes of sustainability and efficient energy use in our everyday lives.

Trustworthiness Through Brand and Quality Choosing insulation strips from reputable manufacturers can make a significant difference. Brands that are specifically known for their quality assurance and rigorous testing standards offer products designed to meet or exceed industry norms. When selecting replacement strips, it is crucial to consider those that guarantee longevity, resistance to wear, and compliance with safety standards. Opting for certified products ensures you receive components that have been scrutinized for both safety and performance. Consumer Experience and Recommendations User reviews and feedback often provide invaluable insights into the practical aspects of oven door insulation strips. Many consumers recommend performing a simple dollar bill test to check the seal integrity. If a bill slides out easily when the door is closed, it might signal the need for a new strip. Moreover, sharing personal testimonials about energy savings and cooking improvements post-replacement can help reinforce the importance of this often-overlooked kitchen component. In Conclusion The oven door insulation strip plays a pivotal role in maintaining an efficient, safe, and effective cooking environment. From material selection to installation and maintenance, each step demands careful consideration. By prioritizing quality and proper upkeep, homeowners not only enhance their cooking experience but also contribute to energy conservation. The significance of this small piece of material extends far beyond the oven, touching upon broader themes of sustainability and efficient energy use in our everyday lives.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

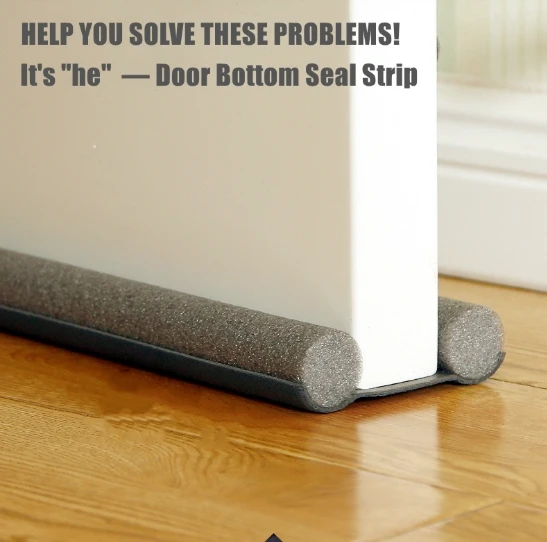

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024