High-Performance Silicone Rubber Sealing Strip for Glass Applications in Various Industries

The Versatile World of Silicone Rubber Glass Seal Strips

Silicone rubber glass seal strips are essential components in various industries, offering exceptional performance in sealing applications. Renowned for their durability, flexibility, and resistance to temperature extremes, silicone rubber is the go-to choice for manufacturers aiming to create effective seals for glass. Whether in windows, doors, aquariums, or automotive applications, these seal strips play a critical role in ensuring optimal performance and longevity.

What are Silicone Rubber Glass Seal Strips?

Silicone rubber seal strips are engineered products made from high-quality silicone material. They are designed to create airtight and watertight seals between glass surfaces and other materials. The unique properties of silicone rubber—such as its excellent elasticity and resistance to degradation—make it ideal for applications where a reliable seal is paramount. These strips come in various shapes, sizes, and configurations to meet the specific requirements of different products.

Key Features and Benefits

1. Durability Silicone rubber is known for its longevity. It can withstand extreme temperatures, ranging from -60°C to 200°C (-76°F to 392°F), without losing its sealing properties. This makes silicone seal strips ideal for both indoor and outdoor applications, where they are exposed to temperature fluctuations and environmental stress.

2. Flexibility The inherent flexibility of silicone rubber enables it to conform to various surfaces and compensate for irregularities. This adaptability ensures a snug fit and enhances the effectiveness of the seal, preventing air and water leaks.

3. Chemical Resistance Silicone rubber exhibits resistance to many chemicals, oils, and solvents, allowing it to maintain performance even in challenging environments. This quality makes silicone seal strips suitable for use in a wide range of industries, including automotive, construction, and food processing.

4. UV Resistance Unlike many other materials, silicone rubber is resistant to UV radiation, which helps prevent deterioration when exposed to sunlight. Therefore, silicone glass seal strips boast longevity and sustained performance in outdoor applications.

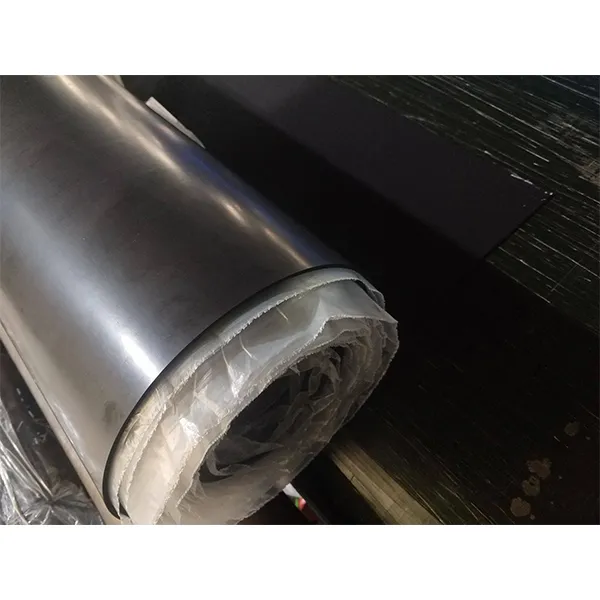

silicone rubber glass seal strip

5. Easy Installation Most silicone rubber glass seal strips are designed for easy installation, often featuring adhesive backing that simplifies the application process. This can reduce labor costs and time, making it an efficient choice for manufacturers and builders alike.

Applications of Silicone Rubber Glass Seal Strips

The versatility of silicone rubber glass seal strips means they find applications in numerous fields

- Construction In commercial and residential buildings, these strips are used around windows and doors to provide insulation and prevent water ingress. They enhance energy efficiency by creating airtight seals that reduce heating and cooling costs.

- Automotive In vehicles, silicone seal strips are employed to seal windshields and side windows. Their ability to withstand vibrations and temperature changes makes them crucial for passenger safety and comfort.

- Aquariums For aquarium construction, silicone seal strips ensure that glass panels are securely bonded and watertight, preventing leaks that could be detrimental to aquatic life.

- Electronics In electronic devices, silicone rubber seal strips are used to protect internal components from dust and moisture, ensuring reliability and durability.

Conclusion

Silicone rubber glass seal strips are indispensable in modern manufacturing and construction. Their unique properties offer unparalleled performance in sealing applications, providing durability, flexibility, and resistance against various environmental factors. As industries continue to evolve, the demand for high-quality sealing solutions like silicone rubber glass seal strips will undoubtedly grow, reinforcing their position as a vital component in ensuring efficiency and reliability across multiple sectors. Whether in residential buildings or complex automotive designs, these seal strips remain a testament to the innovation and functionality of modern materials engineering.

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024