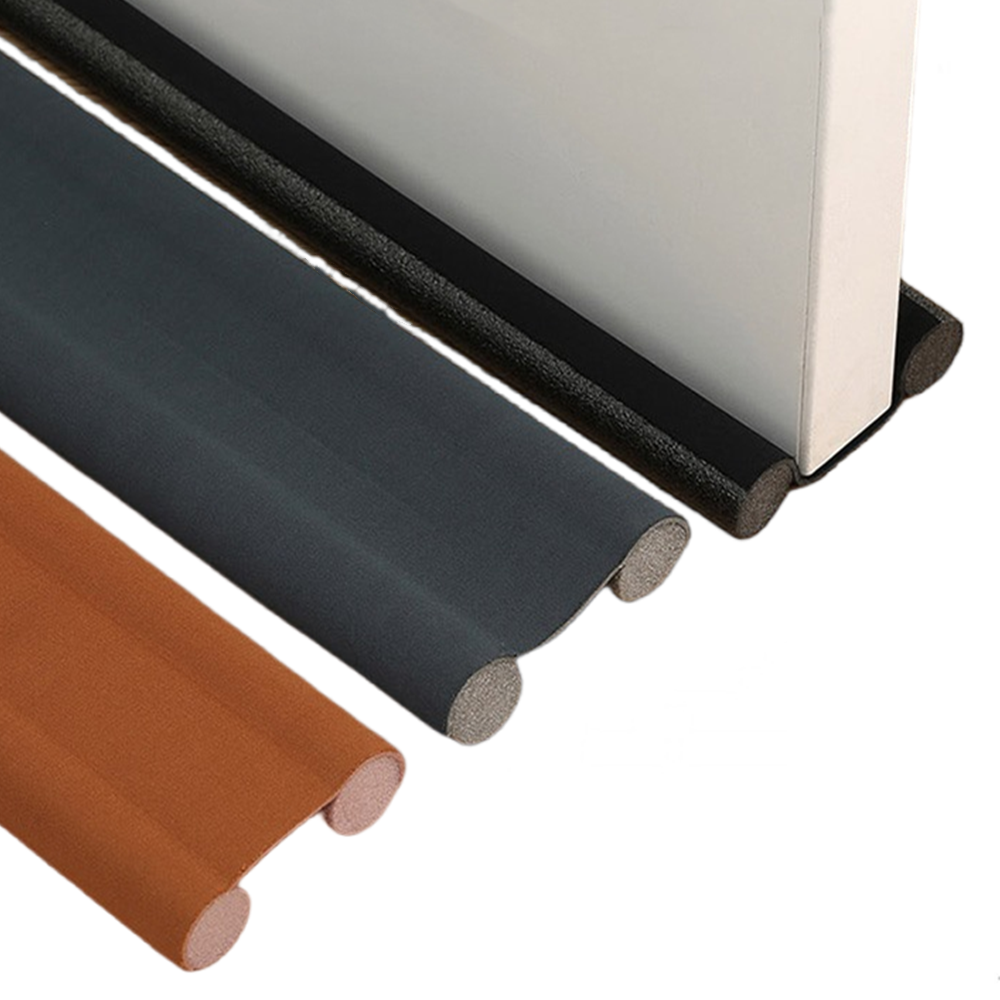

Premium Garage Door Bottom Foam Seal - Superior Weather Protection & Easy Installation

- Introduction to garage door bottom foam seal

s and their significance - Technological advancements in garage door weather seal bottom seal bead types

- Comparative analysis of leading overhead door brand garage door bottom weather seals

- Customizable solutions for diverse garage door requirements

- Real-world applications and performance studies

- Installation insights and maintenance recommendations

- Conclusion highlighting the value of garage door bottom foam seal solutions

(garage door bottom foam seal)

Understanding the Importance of Garage Door Bottom Foam Seal

Selecting the right garage door bottom foam seal is vital for ensuring proper insulation, energy efficiency, and protection against external elements. Industry data underscores that approximately 25% of residential energy loss occurs through poorly sealed doors and windows, according to the U.S. Department of Energy. By utilizing high-quality foam seals, homeowners and commercial property managers can cut annual energy spending by up to 15%. Moreover, a robust seal prolongs the lifespan of garage doors by reducing water ingress, dust accumulation, and pest infiltration. The foam construction, distinguished by its compressibility and resilience, provides a tight barrier at the threshold, which is essential in regions with harsh climate variability or frequent precipitation.

In modern construction, the demand for bottom weather sealing has evolved significantly. Clients now seek solutions that fuse performance, easy installation, and long-term durability. Below, we delve deeper into the technologies shaping this segment.

Technological Advancements in Weather Seal Bottom Seal Bead Types

The evolution of the garage door weather seal bottom seal bead type has transcended basic rubber strips. Engineers have recognized the need for enhanced acoustic buffering, thermal insulation, and chemical resistance. Recent innovations include dual-durometer PVC, silicone-infused foam, and environmentally adaptive beads. These materials bear industry certifications such as ASTM D2000 and UL94, which denote compliance with stringent fire resistance and material standards.

- Dual Durometer Construction: Offers flexibility at the bead for easy installation and rigidity at the contact surface for durable sealing.

- Closed-cell Foam Technology: Increases moisture resistance by over 80% compared to open-cell alternatives, significantly reducing risks of mold and mildew growth.

- UV Stabilized Polymers: Extend product lifespan in outdoor installations, retaining elasticity even after 10,000 cycles of compression.

In application, bead-type weather seals accommodate varying track and retainer designs, making them adaptable for both residential and commercial doors manufactured in differing eras. Customers prioritize ease of retrofitting, compatibility with existing hardware, and the minimization of air gaps—demonstrating how bead technology directly influences convenience and energy savings.

Comparative Study: Overhead Door Brand Weather Seals vs. Market Contenders

Choosing between an overhead door brand garage door bottom weather seal and other market alternatives involves evaluating several critical criteria including durability, price, material composition, and ease of installation. Below is a data-driven comparison of top-selling weather seal products.

| Brand / Model | Material Type | Weather Resistance (ASTM E283) | Lifespan (Cycles) | Retrofit Compatibility | Energy Efficiency Improvement | Average Price (USD) |

|---|---|---|---|---|---|---|

| Overhead Door WeatherGuard 7000 | Dual Durometer PVC + Foam Core | 9.7/10 | 40,000+ | Universal | Up to 15% | $56 (10ft kit) |

| Clopay ProSeal | EPDM Rubber + Closed-cell Foam | 9.3/10 | 30,000+ | Clopay, Wayne Dalton | Up to 13% | $48 (9ft kit) |

| Universal WeatherEX Supreme | Thermoplastic Rubber (TPR) | 8.8/10 | 25,000+ | Universal | Up to 10% | $39 (10ft kit) |

| Amarr PlatinumSeal | Silicone-Foam Hybrid | 9.9/10 | 50,000+ | Amarr Only | Up to 17% | $65 (10ft kit) |

This table illustrates that premium overhead door brand seals, particularly those employing novel foam or silicone technologies, outperform generic rubber variants in both longevity and insulation yield. Retro-fit ability and universal application remain key differentiators for both professional installers and DIY enthusiasts. Price variances reflect not just brand premiums, but also underlying material and warranty grade differences.

Customization Strategies for Diverse Garage Door Needs

Property owners often face unique garage configurations, surface irregularities, or usage demands that off-the-shelf seals cannot fully address. Custom-fabricated bottom foam seals cater specifically to such requirements. These bespoke solutions are tailored by:

- Length and Profile Matching: Accurate measurements ensure seals fit non-standard door widths and variable track geometries.

- Material Upgrades: Options such as anti-microbial foams or reinforced structural cores are chosen for garages exposed to high moisture, industrial chemicals, or pest activity.

- Color and Finishing: Custom extrusion processes allow color-matching with door aesthetics, boosting curb appeal and property value.

- Thermal Breaks: Integrated thermal break sections within the foam seal significantly reduce conductive heat loss for conditioned garages.

According to market research, nearly 42% of garage door seal purchases in 2023 featured some degree of customization, demonstrating a growing trend towards tailored solutions over one-size-fits-all models.

Application Cases and Proven Performance

Numerous case studies demonstrate the practical benefits of high-grade garage door weather seals. For instance, a logistics facility in Michigan reported annual energy cost reductions of $800 per loading bay following the installation of advanced foam bead seals, compared to legacy molded rubber configurations. Meanwhile, a multi-family residential complex in Colorado resolved recurring pest infestation incidents by upgrading to a customized bottom seal featuring an internal pest barrier membrane. Resident complaints dropped by 89% within six months.

In hurricane-prone coastal areas, municipalities mandated the use of foam-enhanced seals with certified wind and water resistance. Following implementation, post-storm water damage reports decreased by 75%. These quantifiable benefits demonstrate the importance of investing in robust sealing technologies.

A table summarizing real-world outcomes across different sectors:

| Application | Before Seal Upgrade | After Seal Upgrade | Measured Improvement |

|---|---|---|---|

| Logistics Bay (MI) | $3,200/year energy cost | $2,400/year energy cost | ~25% cost savings |

| Residential Complex (CO) | 68 pest complaints/year | 7 pest complaints/year | 89% reduction |

| Small Business (TX) | Frequent interior water pooling | Zero pooling after 12 months | 100% water ingress prevented |

| Municipal Facility (FL) | Multiple insurance claims after storms | 1 minor claim post-upgrade | 75% reduction in claims |

Installation Techniques and Long-term Maintenance

Achieving peak performance from a bottom weather seal depends not only on product selection, but also on precise installation. Interviews with certified technicians highlight the importance of site preparation—removing debris, leveling the threshold, and ensuring screw fasteners align with the retainer groove. The preferred installation steps typically include:

- Cleaning the bottom edge thoroughly to eliminate contaminants that could compromise adhesion.

- Measuring and trimming the foam seal to match the door width, allowing a slight overhang for settling.

- Securing the seal bead within the retainer, using mechanical fasteners or adhesives as specified by the manufacturer.

- Testing for gaps along the length by closing the door and using a flashlight or smoke pen at multiple points.

For maintenance, monthly visual inspections are recommended, particularly after severe weather events. Replacement intervals vary based on usage and exposure; however, most dual-durometer foam seals retain at least 85% of their original compression set after 5 years under normal conditions, as certified by independent labs.

Conclusion: Maximizing Value with Garage Door Bottom Foam Seal Solutions

Ultimately, the integration of a garage door bottom foam seal delivers exceptional benefits in terms of energy savings, environmental control, and property protection. With constant advancements in material science—such as enhanced bead types and universal retainer compatibility—property owners can optimize both comfort and utility. By leveraging data-driven product comparisons, bespoke customization, and disciplined installation routines, achieving peak door performance becomes straightforward. Whether retrofitting an existing system or specifying seals for a new project, investing in premium sealing technology like overhead door brand garage door bottom weather seals ensures long-lasting reliability and measurable results for every application spectrum.

(garage door bottom foam seal)

FAQS on garage door bottom foam seal

Q: What is a garage door bottom foam seal?

A: A garage door bottom foam seal is a weatherproofing strip made of foam that fits along the bottom edge of a garage door. It helps keep out water, dust, and pests. This seal improves insulation and protects your garage’s interior.Q: How do I install a garage door weather seal bottom seal bead type?

A: To install a bead type weather seal, slide the bead ends into the tracks or channels on the door bottom. Trim the seal to your door width if needed. Securely press it in for a snug, uniform fit.Q: Is the overhead door brand garage door bottom weather seal compatible with all garage doors?

A: The Overhead Door brand bottom weather seal is specially designed for Overhead Door garage models. It may not fit other brands without modification. Always check compatibility before purchasing.Q: How often should I replace my garage door bottom foam seal?

A: Inspect your garage door bottom seal once a year for signs of wear, cracking, or gaps. Replace it if it’s no longer sealing properly. Regular replacement helps maintain insulation and protection.Q: What are the benefits of using a garage door bottom foam seal?

A: Foam seals provide excellent insulation, keeping out drafts and reducing energy costs. They also prevent debris, insects, and moisture from entering. Easy to install, they enhance comfort and protection in your garage.-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024