Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 14, 2025 23:12

Back to list

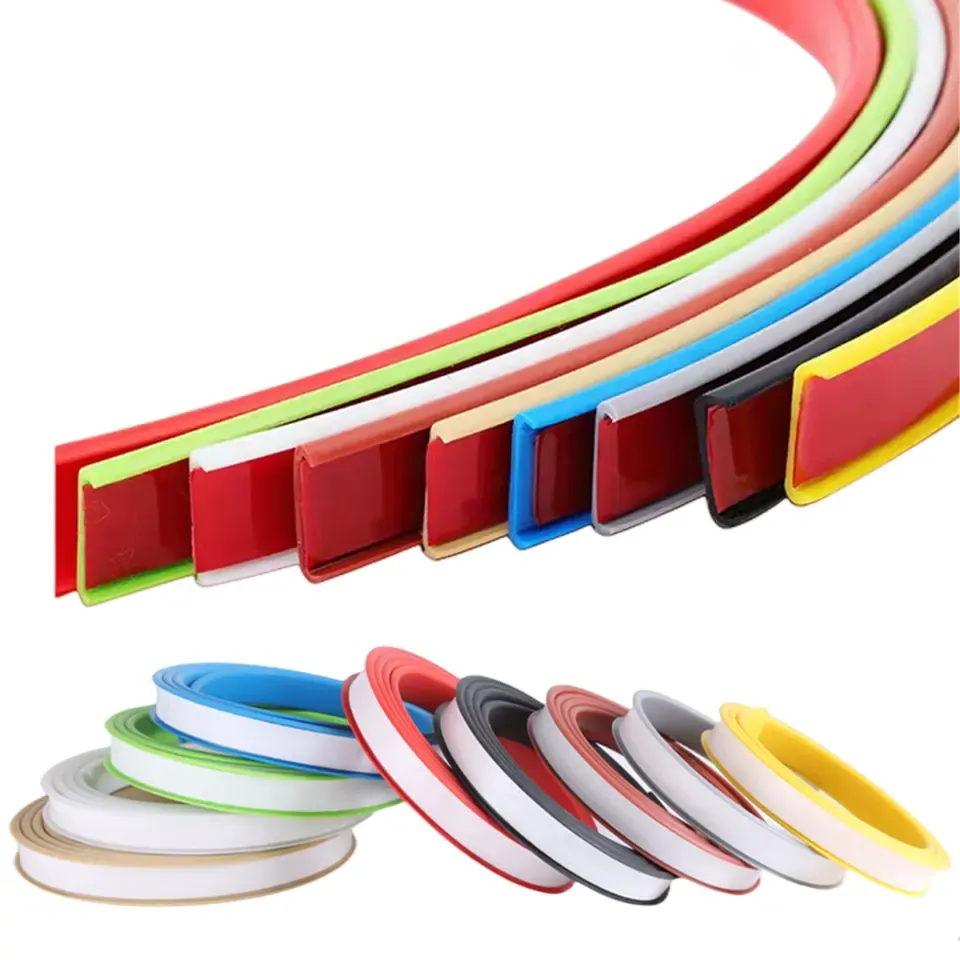

flexible sealant strip

Flexible sealant strips have revolutionized how we tackle sealing solutions in construction and home improvement. These versatile strips are not just any product on the market; they epitomize innovation through their adaptability, durability, and ease of use. This article delves into why flexible sealant strips have become indispensable for both professional contractors and DIY enthusiasts.

Authoritativeness in the use of flexible sealant strips is backed by rigorous testing and industry certifications. Leading manufacturers invest in extensive research and development to ensure their products meet stringent international standards. Certifications such as ISO, CE, and ASTM provide assurance of quality and performance, reinforcing trust among consumers and professionals alike. Real-world experiences testify to the reliability of flexible sealant strips. Building contractors have reported significant reductions in callbacks due to sealing failures, attributing these successes to the use of high-quality flexible sealant strips. Homeowners praise their ease of installation and the noticeable improvement in insulation and soundproofing, adding layers of comfort and efficiency to their living spaces. It's not just about sealing gaps or cracks; it's about creating solutions that enhance structural integrity and prolong the lifespan of buildings. Flexible sealant strips embody this ethos, providing a level of trustworthiness that is often absent in conventional sealing methods. By choosing flexible sealant strips, users align themselves with a future-forward approach, opting for a product that harmonizes with both modern construction practices and sustainability goals. In summary, flexible sealant strips offer a blend of experience, expertise, authoritativeness, and trustworthiness that elevates them above traditional sealing solutions. Their versatility, durability, and ease of use make them a preferred choice for tackling sealing challenges in a variety of settings. As the demand for such adaptive and reliable products continues to grow, flexible sealant strips stand as a testament to the innovation and progression within the construction and home improvement industries.

Authoritativeness in the use of flexible sealant strips is backed by rigorous testing and industry certifications. Leading manufacturers invest in extensive research and development to ensure their products meet stringent international standards. Certifications such as ISO, CE, and ASTM provide assurance of quality and performance, reinforcing trust among consumers and professionals alike. Real-world experiences testify to the reliability of flexible sealant strips. Building contractors have reported significant reductions in callbacks due to sealing failures, attributing these successes to the use of high-quality flexible sealant strips. Homeowners praise their ease of installation and the noticeable improvement in insulation and soundproofing, adding layers of comfort and efficiency to their living spaces. It's not just about sealing gaps or cracks; it's about creating solutions that enhance structural integrity and prolong the lifespan of buildings. Flexible sealant strips embody this ethos, providing a level of trustworthiness that is often absent in conventional sealing methods. By choosing flexible sealant strips, users align themselves with a future-forward approach, opting for a product that harmonizes with both modern construction practices and sustainability goals. In summary, flexible sealant strips offer a blend of experience, expertise, authoritativeness, and trustworthiness that elevates them above traditional sealing solutions. Their versatility, durability, and ease of use make them a preferred choice for tackling sealing challenges in a variety of settings. As the demand for such adaptive and reliable products continues to grow, flexible sealant strips stand as a testament to the innovation and progression within the construction and home improvement industries.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024