Exploring the Benefits and Applications of MDF Edge Tape in Modern Furniture Design

Understanding MDF Edge Tape A Key Component in Furniture and Interior Design

Medium Density Fiberboard (MDF) has become a popular material in furniture making and interior design due to its versatility, affordability, and smooth surface. However, to enhance its appeal and longevity, MDF is often paired with edge tape. MDF edge tape plays a significant role in improving the overall aesthetics and functionality of MDF products. In this article, we will explore what MDF edge tape is, its benefits, types, and applications in the design industry.

What is MDF Edge Tape?

MDF edge tape is a thin strip of material applied to the exposed edges of MDF panels. These edges are typically raw and prone to damage, moisture absorption, and wear over time. Edge tape serves as a protective layer, preventing these issues while also providing a finished look. The tape is available in various materials including PVC, melamine, and veneer, each offering unique benefits and appearances.

Benefits of MDF Edge Tape

1. Protection One of the primary functions of MDF edge tape is to safeguard the edges from environmental factors such as moisture, staining, and physical damage. This is particularly important in furniture and cabinetry, where exposed edges can deteriorate over time.

2. Aesthetic Appeal Edge tape enhances the visual appeal of MDF products by providing a seamless finish between the surface and edges. It allows for color matching and can create a uniform look across different pieces.

3. Durability High-quality edge tape adds durability to MDF products, ensuring that they withstand wear and tear in high-traffic areas. This durability extends the lifespan of furniture and fixtures, making them more cost-effective in the long run.

4. Ease of Installation MDF edge tape is relatively easy to apply, with various methods available including hot-melt adhesives and peel-and-stick options. This ease of use makes it a popular choice among manufacturers and DIY enthusiasts alike.

Types of MDF Edge Tape

mdf edge tape

There are several types of MDF edge tape, each suited for different applications and preferences

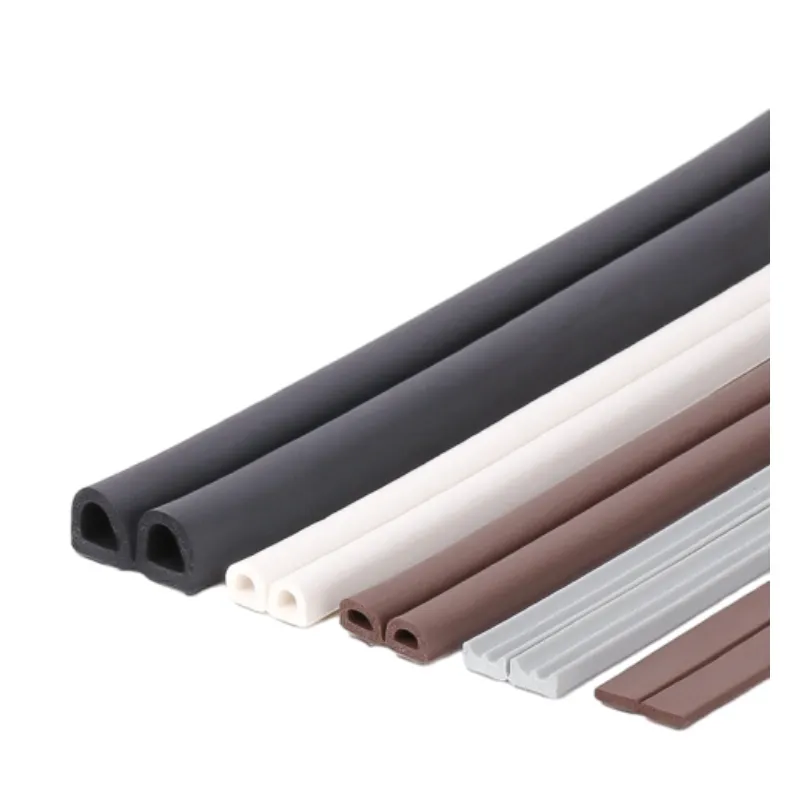

1. PVC Edge Tape Known for its high durability and resistance to moisture, PVC edge tape is commonly used in kitchens and bathrooms. It comes in a variety of colors and finishes, making it a flexible option for many design styles.

2. Melamine Edge Tape Made from melamine resin, this edge tape is often used in laminate surfaces. It provides a sleek finish and is available in various patterns and colors to match MDF surfaces.

3. Veneer Edge Tape For a more natural look, veneer edge tape is ideal. Made from real wood, it offers the aesthetic of solid wood at a fraction of the cost. It is often used in high-end furniture design.

Applications of MDF Edge Tape

MDF edge tape is widely used in various applications, including

- Furniture Manufacturing From cabinets to tables, MDF edge tape enhances the look and longevity of furniture pieces. - Interior Design Designers often use MDF edge tape in custom cabinetry and built-ins to create seamless integrations with the surrounding decor. - DIY Projects DIY enthusiasts frequently use MDF and edge tape for home improvement projects, crafting everything from shelves to entertainment centers.

Conclusion

MDF edge tape is an essential component in the world of furniture manufacturing and interior design. Its protective qualities, aesthetic enhancements, and ease of installation make it a popular choice among professionals and DIYers alike. By understanding the various types of MDF edge tape and their applications, one can make informed decisions that enhance the beauty and durability of their projects. Whether for a simple home repair or an intricate furniture design, MDF edge tape is a small detail that makes a significant impact.

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024