Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 19, 2025 09:18

Back to list

Drainage Non Slip Mat, Commercial PVC Floor Mat

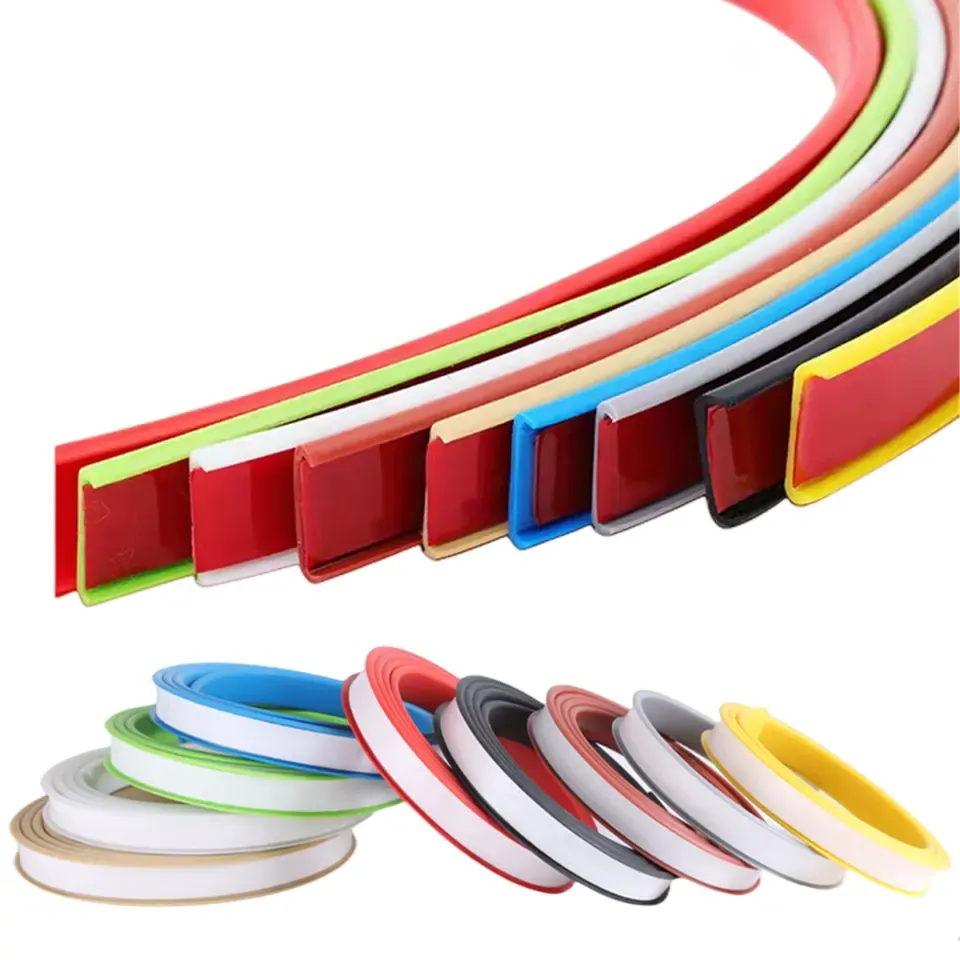

Edge guards are essential components in various industries, offering protection, enhancing durability, and adding aesthetic appeal to products and environments. As an experienced SEO specialist, I am sharing insights into why edge guards are crucial and how they benefit different sectors.

In the consumer goods sector, edge guards are often integrated into products such as home appliances, electronic devices, and children's toys. For appliances and electronics, edge guards protect against damage from drops or knocks, while in the case of toys, they are used to soften hard edges, making them safer for children. The use of non-toxic and environmentally friendly materials in the manufacture of these edge guards is a growing trend, reflecting increased consumer awareness and demand for sustainable products. The materials used for edge guards vary, each offering specific advantages. Rubber edge guards offer flexibility and impact resistance, making them ideal for environments with high movement or vibration. Metal edge guards, often made from aluminum or stainless steel, provide robust protection against heavy and repeated impact and are thus favored in industrial settings. Plastic edge guards, on the other hand, are lightweight and available in various colors, catering to applications where visual harmony with the product is paramount. Design innovation continues to drive the development of edge guards, with manufacturers increasingly focusing on creating products that not only function effectively but also enhance the end-user experience. Advanced edge guard designs now incorporate features such as easy installation, weatherproofing, and thermal resistance, ensuring that they meet the diverse needs of modern industries. The application, material choice, and design considerations of edge guards are guided by expertise and authority in their respective fields. Experts in product design and material science ensure that edge guards not only fulfill practical functions but also comply with safety standards and environmental regulations. Trust in these products is thus built on both their track record in protecting assets and their continuous evolution to meet new challenges. In conclusion, edge guards are integral components that provide critical protection and enhance the usability and aesthetic of products across various industries. Through innovation and adherence to high standards of design and functionality, edge guards play a crucial role in product longevity, safety, and consumer satisfaction. Their widespread application across sectors is a testament to their importance and the trust placed in them by manufacturers and consumers alike.

In the consumer goods sector, edge guards are often integrated into products such as home appliances, electronic devices, and children's toys. For appliances and electronics, edge guards protect against damage from drops or knocks, while in the case of toys, they are used to soften hard edges, making them safer for children. The use of non-toxic and environmentally friendly materials in the manufacture of these edge guards is a growing trend, reflecting increased consumer awareness and demand for sustainable products. The materials used for edge guards vary, each offering specific advantages. Rubber edge guards offer flexibility and impact resistance, making them ideal for environments with high movement or vibration. Metal edge guards, often made from aluminum or stainless steel, provide robust protection against heavy and repeated impact and are thus favored in industrial settings. Plastic edge guards, on the other hand, are lightweight and available in various colors, catering to applications where visual harmony with the product is paramount. Design innovation continues to drive the development of edge guards, with manufacturers increasingly focusing on creating products that not only function effectively but also enhance the end-user experience. Advanced edge guard designs now incorporate features such as easy installation, weatherproofing, and thermal resistance, ensuring that they meet the diverse needs of modern industries. The application, material choice, and design considerations of edge guards are guided by expertise and authority in their respective fields. Experts in product design and material science ensure that edge guards not only fulfill practical functions but also comply with safety standards and environmental regulations. Trust in these products is thus built on both their track record in protecting assets and their continuous evolution to meet new challenges. In conclusion, edge guards are integral components that provide critical protection and enhance the usability and aesthetic of products across various industries. Through innovation and adherence to high standards of design and functionality, edge guards play a crucial role in product longevity, safety, and consumer satisfaction. Their widespread application across sectors is a testament to their importance and the trust placed in them by manufacturers and consumers alike.

Next:

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024