Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 17, 2025 21:10

Back to list

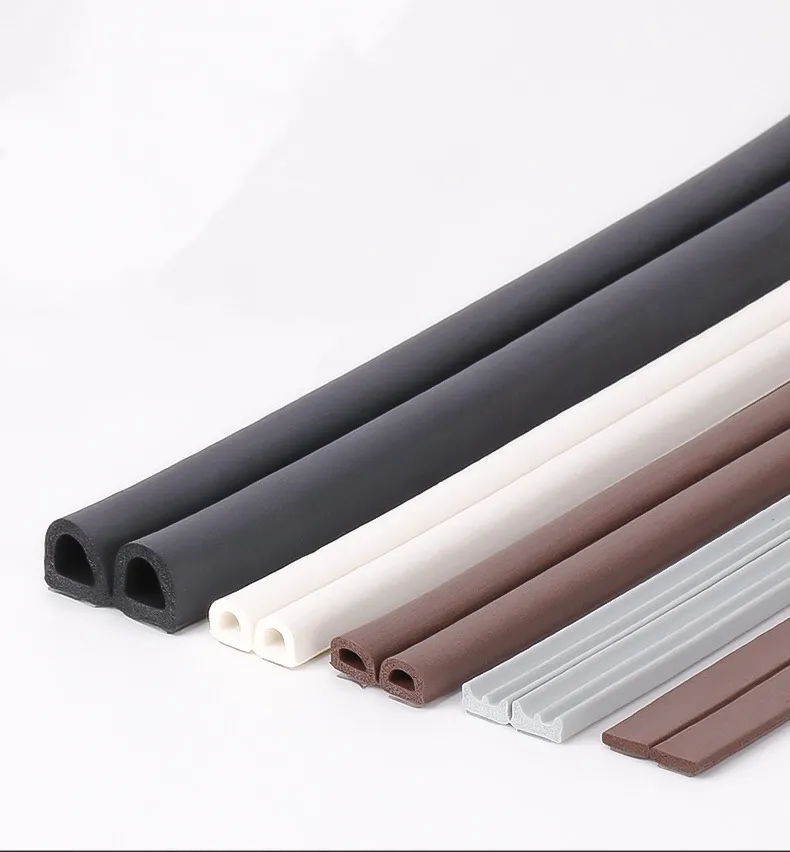

edge banding tape sizes

Navigating the world of edge banding tape sizes involves more than merely choosing a width or length; it’s about understanding the nuances of material compatibility, application methods, and the operational efficiencies they bring to woodworking projects. Through a deeper exploration of edge banding tapes, woodworkers, designers, and manufacturers can enhance both the aesthetic and structural qualities of furniture and cabinetry.

For more intricate projects requiring precision and less aggressive adhesion, peel-and-stick tapes offer ease of use with minimal equipment, allowing for adjustable and temporary placement before making the final cut. This versatility makes them perfect for bespoke or batch production, where adjustments and exact fits are crucial. To ensure the professionality and quality of work, it is crucial for woodworking professionals to select edge banding tapes not only based on size but also on compatibility with the material in use. Different core materials, such as MDF or particleboard, respond uniquely to various adhesives and banding thicknesses. Thus, mastering the relationship between these materials and tape sizes guarantees a durable bond while enhancing the aesthetic appeal of the finished product. The choice of edge banding tape size should also consider environmental factors, such as humidity and temperature variations, affecting adhesive performance. Professionals experienced in edge banding application understand that selecting the proper size involves predicting environmental challenges the furniture will face, ensuring that the edge banding can withstand these stresses without loosening or deteriorating. In summation, the expertise required in selecting edge banding tape sizes extends beyond mere dimensional specifications. It involves a comprehensive understanding of the project's requirements, material compatibility, application techniques, and environmental considerations. Skilled application of this knowledge leads to not only visually pleasing and functional pieces but also establishes a standard of quality and durability that industry professionals and consumers expect from modern woodworking projects. The meticulous selection of edge banding tape sizes reflects a commitment to craftsmanship and a deep respect for the materials used, reinforcing the value and integrity of each completed piece.

For more intricate projects requiring precision and less aggressive adhesion, peel-and-stick tapes offer ease of use with minimal equipment, allowing for adjustable and temporary placement before making the final cut. This versatility makes them perfect for bespoke or batch production, where adjustments and exact fits are crucial. To ensure the professionality and quality of work, it is crucial for woodworking professionals to select edge banding tapes not only based on size but also on compatibility with the material in use. Different core materials, such as MDF or particleboard, respond uniquely to various adhesives and banding thicknesses. Thus, mastering the relationship between these materials and tape sizes guarantees a durable bond while enhancing the aesthetic appeal of the finished product. The choice of edge banding tape size should also consider environmental factors, such as humidity and temperature variations, affecting adhesive performance. Professionals experienced in edge banding application understand that selecting the proper size involves predicting environmental challenges the furniture will face, ensuring that the edge banding can withstand these stresses without loosening or deteriorating. In summation, the expertise required in selecting edge banding tape sizes extends beyond mere dimensional specifications. It involves a comprehensive understanding of the project's requirements, material compatibility, application techniques, and environmental considerations. Skilled application of this knowledge leads to not only visually pleasing and functional pieces but also establishes a standard of quality and durability that industry professionals and consumers expect from modern woodworking projects. The meticulous selection of edge banding tape sizes reflects a commitment to craftsmanship and a deep respect for the materials used, reinforcing the value and integrity of each completed piece.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024