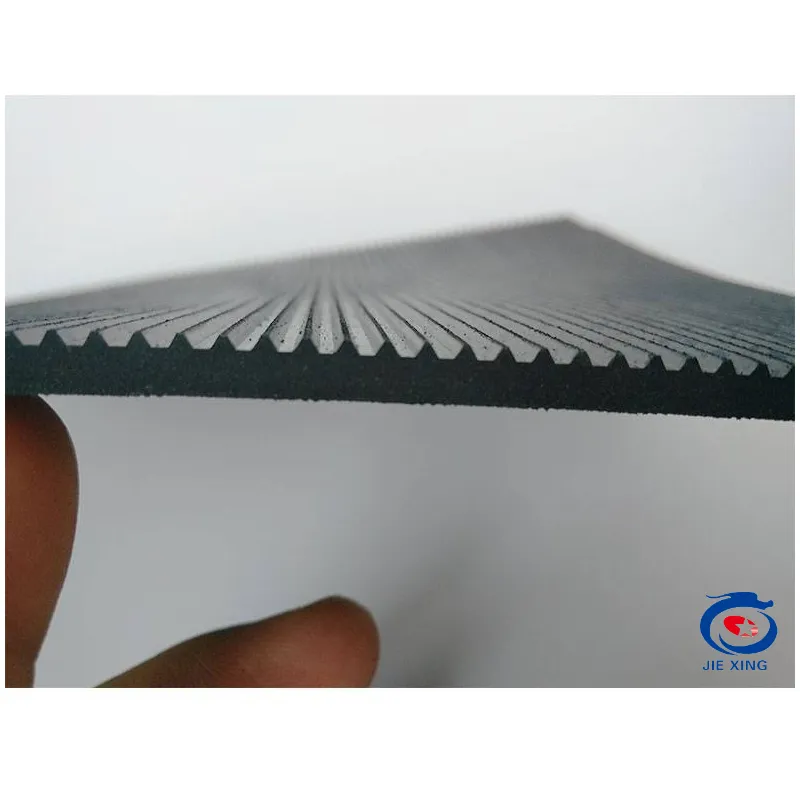

edge banding strip

Understanding Edge Banding Strips A Key Component in Furniture and Cabinetry

In the world of furniture manufacturing and cabinetry, edge banding strips play a crucial role in both aesthetics and functionality. These narrow strips of material are applied to the exposed edges of particleboard, MDF, or plywood to create a finished, polished look while protecting the underlying substrate. This process not only enhances the appearance of furniture but also improves its durability, making edge banding an essential consideration for both manufacturers and consumers.

What is Edge Banding?

Edge banding refers to the process of covering the raw edges of wood panels with a thin strip of material, commonly referred to as an edge banding strip. These strips can be made from various materials, including wood veneers, PVC, ABS, melamine, and laminate, each of which offers distinct advantages. Wood veneer strips provide a natural look, helping to maintain a unified aesthetic, while PVC and ABS options are often more durable and resistant to moisture and wear.

The choice of edge banding material is influenced by several factors, including the intended use of the furniture, budget constraints, and desired appearance. For example, high-end cabinetry often features solid wood veneer edge banding, which aligns with the overall design ethos of quality and craftsmanship.

Benefits of Edge Banding Strips

One of the primary benefits of using edge banding strips is their ability to protect the edges of furniture panels. Raw edges are prone to chipping, cracking, and moisture absorption, which can compromise the integrity of the material. By applying edge banding, manufacturers can create a more robust product that stands up to daily wear and tear.

edge banding strip

In addition to protection, edge banding also enhances the aesthetic appeal of furniture. A clean and finished look contributes to the overall design, allowing for seamless integration into various interiors. Available in numerous colors, textures, and finishes, edge banding can match or complement the surface of the panels it adorns, providing a cohesive appearance.

Furthermore, edge banding strips are a cost-effective solution for achieving a high-end look without the expense of solid wood panels. By using lower-cost substrates and applying quality edge banding, manufacturers can offer visually appealing and durable products at a more affordable price point.

The Edge Banding Process

The application of edge banding is a precise process that typically involves several steps. First, the edges of the panels are prepared to ensure they are smooth and free from debris. Next, the edge banding strip is cut to size and applied using adhesive. This can be done manually or with automated edge banding machines, which allow for higher efficiency and consistency.

Once the edge banding is in place, excess material is trimmed away, and the edges are polished to ensure a seamless fit. This final touch adds to the overall quality of the finished product, further enhancing its durability and visual appeal.

Conclusion

Edge banding strips are an indispensable component in the furniture and cabinetry industry. They offer an array of benefits, including enhanced durability, aesthetic appeal, and cost-effectiveness. As consumers increasingly seek both quality and value in their furniture choices, the role of edge banding will continue to be vital. Whether you are a manufacturer looking to improve your products or a consumer interested in the finer details of furniture design, understanding edge banding can provide valuable insight into the craftsmanship that goes into creating beautiful and functional pieces.

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024