Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 17, 2025 13:47

Back to list

High Density Light Truck Bed Rubber Mat 4mm 141.5×205cm C type

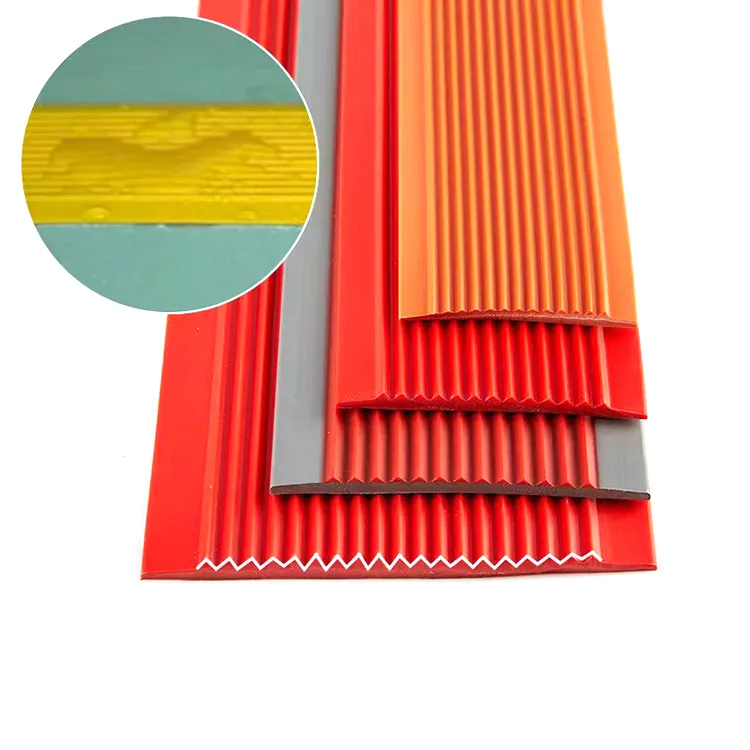

Edge banding has become a cornerstone in the world of woodworking and furniture design, offering both aesthetic and functional benefits that are indispensable for quality craftsmanship. As someone deeply entrenched in this industry, understanding the core advantages and methodologies associated with edge banding can significantly influence a product's appeal and durability.

Trustworthiness in this domain comes from adhering to high standards of quality and customer satisfaction. Professionals ensure their work stands up to scrutiny by meticulously selecting only top-tier materials known for their longevity and by employing precise application techniques that guarantee a strong, lasting bond. Furthermore, showcasing testimonials and case studies from previous work helps in building credibility amongst potential clients. Each project, from residential kitchen installations to large commercial contracts, should reflect adherence to promised standards and customer specifications. Edge banding is not only about practicality but also about creating a product that exudes sophistication. The ongoing trends in minimalist, modern design have seen a rise in the demand for sleek, edge banded finishes that mesh well with contemporary interiors. Furniture designers are now integrating edge banding into their pieces not just for functionality, but as a defining stylistic element. This trend illustrates the growing importance of edge banding in delivering products that meet both utilitarian and aesthetic criteria in today's competitive market. With a future that leans heavily into sustainable practices, edge banding also serves an environmental role. Many edge bands now utilize recycled materials or environmentally friendly adhesives, reducing the ecological footprint. This aligns with a broader industry move towards using eco-conscious practices and materials in production. For companies and consumers alike, choosing products with sustainably sourced edge banding reflects their commitment to environmental responsibility. In summary, edge banding is a vital component in not only protecting and extending the life of furniture products but also in asserting a brand's reputation for quality and innovation. With edges that bear testament to a craftsman's skill and an eye for detail, edge banded products continue to stand out in their ability to blend functionality with exquisite design. As the industry evolves, so too does the scope and sophistication of edge banding, proving itself as an essential element in creating products that not only meet but exceed modern customer expectations.

Trustworthiness in this domain comes from adhering to high standards of quality and customer satisfaction. Professionals ensure their work stands up to scrutiny by meticulously selecting only top-tier materials known for their longevity and by employing precise application techniques that guarantee a strong, lasting bond. Furthermore, showcasing testimonials and case studies from previous work helps in building credibility amongst potential clients. Each project, from residential kitchen installations to large commercial contracts, should reflect adherence to promised standards and customer specifications. Edge banding is not only about practicality but also about creating a product that exudes sophistication. The ongoing trends in minimalist, modern design have seen a rise in the demand for sleek, edge banded finishes that mesh well with contemporary interiors. Furniture designers are now integrating edge banding into their pieces not just for functionality, but as a defining stylistic element. This trend illustrates the growing importance of edge banding in delivering products that meet both utilitarian and aesthetic criteria in today's competitive market. With a future that leans heavily into sustainable practices, edge banding also serves an environmental role. Many edge bands now utilize recycled materials or environmentally friendly adhesives, reducing the ecological footprint. This aligns with a broader industry move towards using eco-conscious practices and materials in production. For companies and consumers alike, choosing products with sustainably sourced edge banding reflects their commitment to environmental responsibility. In summary, edge banding is a vital component in not only protecting and extending the life of furniture products but also in asserting a brand's reputation for quality and innovation. With edges that bear testament to a craftsman's skill and an eye for detail, edge banded products continue to stand out in their ability to blend functionality with exquisite design. As the industry evolves, so too does the scope and sophistication of edge banding, proving itself as an essential element in creating products that not only meet but exceed modern customer expectations.

Next:

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

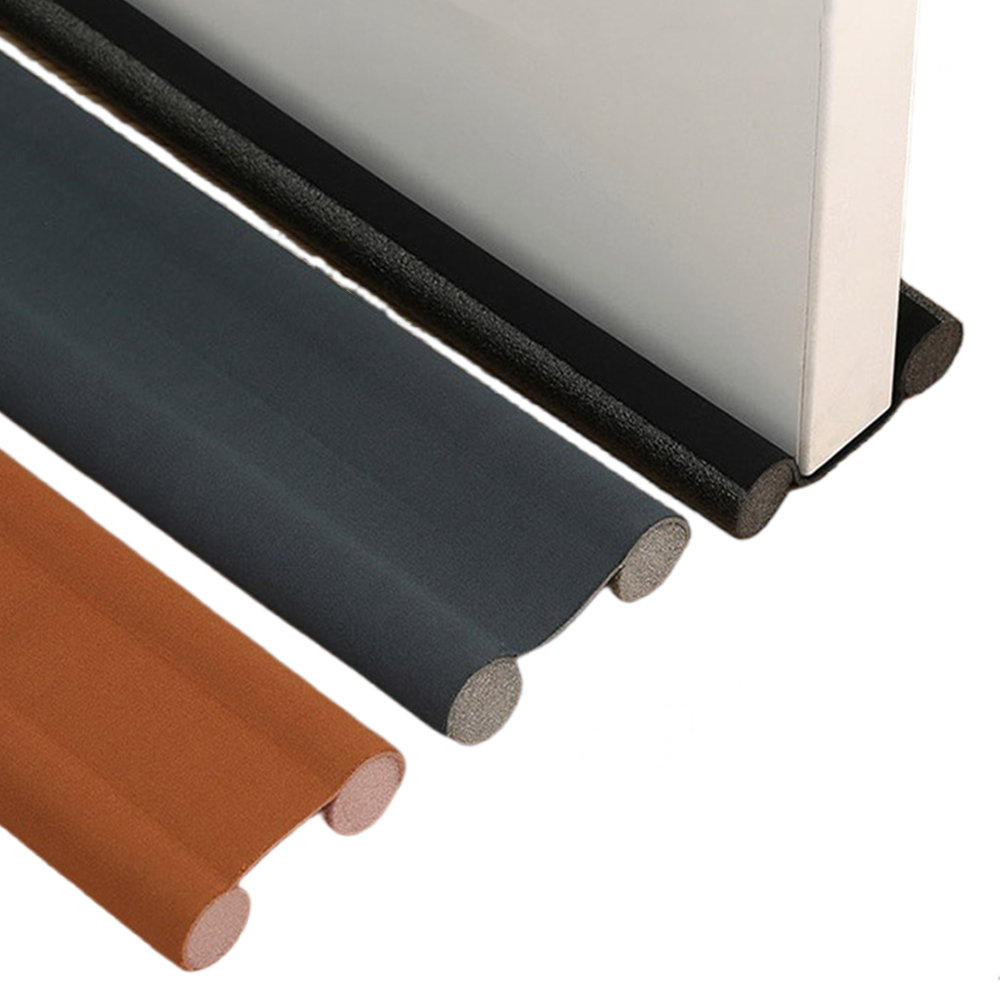

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024