Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 19, 2025 04:28

Back to list

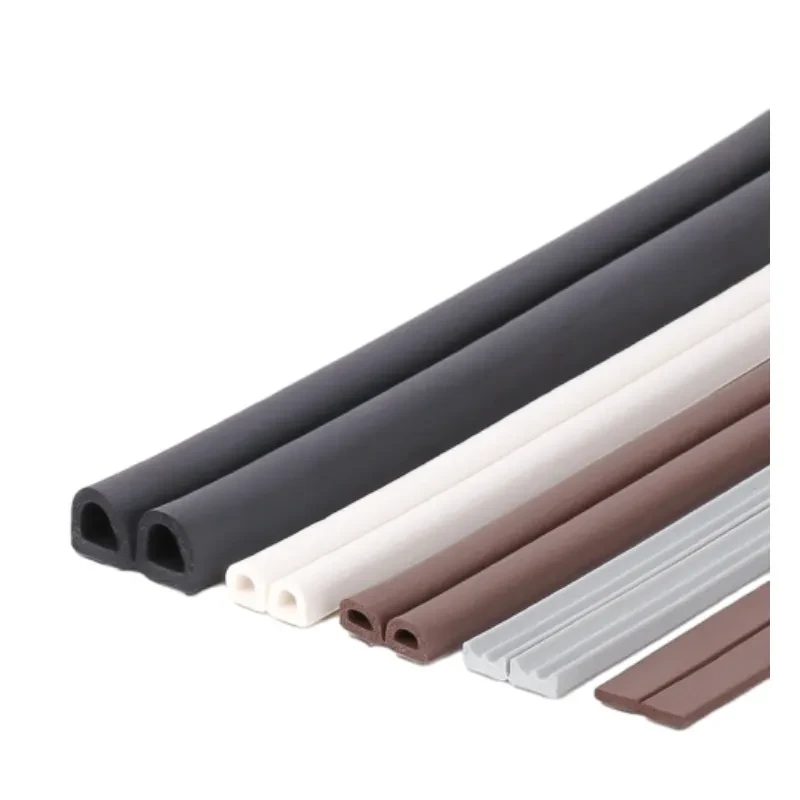

e3 pvc edge band

E3 PVC edge banding has seen a remarkable rise in both popularity and application within the furniture and cabinetry industry. This surge can be attributed to the unique blend of durability, aesthetic appeal, and cost-effectiveness offered by E3 PVC edge bands. Designed to provide a seamless finish to raw edges, these edge bands elevate the look and longevity of various structures, making them an indispensable component in modern carpentry.

The trustworthiness of E3 PVC edge banding further extends to its eco-friendly production process. As environmental sustainability becomes an integral aspect of materials manufacturing, E3 PVC edge bands are crafted with non-toxic additives, ensuring they are free from harmful chemicals that could detrimentally affect both installers and end-users. This commitment to safety and sustainability strengthens the reliability of E3 PVC products in the eyes of eco-conscious consumers and businesses. From a product standpoint, the versatility of E3 PVC edge bands cannot be overstated. Available in a myriad of colors, textures, and finishes, these bands allow for a high degree of customization that caters to diverse aesthetic preferences. Whether mimicking the look of a polished wood grain or a sleek modern finish, E3 PVC edge bands provide a cost-effective solution without compromising style or quality. As user demands shift towards more personalized designs, this adaptability becomes a significant competitive advantage. Ultimately, the decision to opt for E3 PVC edge banding is underscored by its pragmatic benefits. The integration of such edge bands results in reduced maintenance costs, as the inherent properties of PVC offer resilience against wear and tear. For installers seeking efficient and reliable performance, the straightforward application process allows for quick installations, ensuring projects are both time and cost-efficient. In conclusion, E3 PVC edge bands are not merely an accessory but a vital component in the construction and design of enduring, stylish, and functional furniture. Their combination of aesthetic versatility, robust performance, and environmental consideration squarely places them at the forefront of edge banding solutions in contemporary carpentry. As the industry continues to evolve, E3 PVC edge bands remain a cornerstone of quality and innovation in craftsmanship.

The trustworthiness of E3 PVC edge banding further extends to its eco-friendly production process. As environmental sustainability becomes an integral aspect of materials manufacturing, E3 PVC edge bands are crafted with non-toxic additives, ensuring they are free from harmful chemicals that could detrimentally affect both installers and end-users. This commitment to safety and sustainability strengthens the reliability of E3 PVC products in the eyes of eco-conscious consumers and businesses. From a product standpoint, the versatility of E3 PVC edge bands cannot be overstated. Available in a myriad of colors, textures, and finishes, these bands allow for a high degree of customization that caters to diverse aesthetic preferences. Whether mimicking the look of a polished wood grain or a sleek modern finish, E3 PVC edge bands provide a cost-effective solution without compromising style or quality. As user demands shift towards more personalized designs, this adaptability becomes a significant competitive advantage. Ultimately, the decision to opt for E3 PVC edge banding is underscored by its pragmatic benefits. The integration of such edge bands results in reduced maintenance costs, as the inherent properties of PVC offer resilience against wear and tear. For installers seeking efficient and reliable performance, the straightforward application process allows for quick installations, ensuring projects are both time and cost-efficient. In conclusion, E3 PVC edge bands are not merely an accessory but a vital component in the construction and design of enduring, stylish, and functional furniture. Their combination of aesthetic versatility, robust performance, and environmental consideration squarely places them at the forefront of edge banding solutions in contemporary carpentry. As the industry continues to evolve, E3 PVC edge bands remain a cornerstone of quality and innovation in craftsmanship.

Next:

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024