Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 18, 2025 03:17

Back to list

Plastic Rubber Stair Nose Edge Trim,Stair Step Edging Protection Decoration Guard For School And Home Use

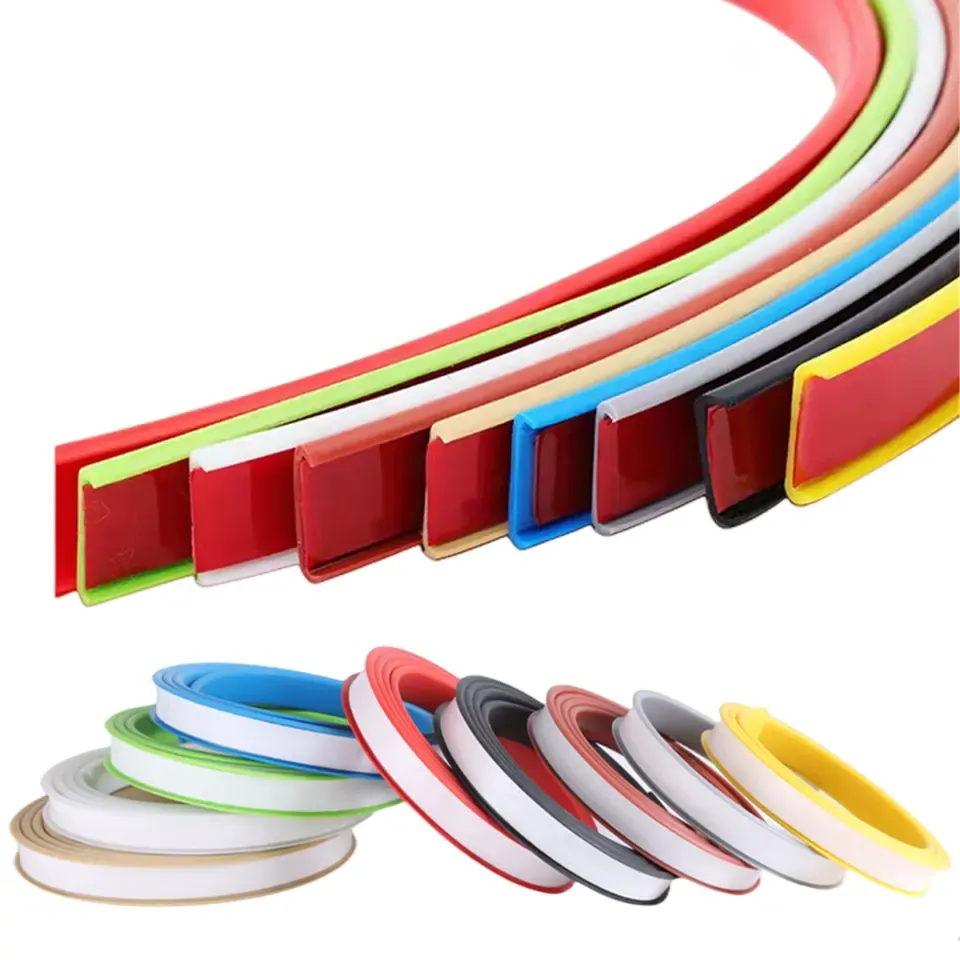

Chipboard edging tape, a versatile product common in carpentry and furniture manufacturing, significantly enhances the appearance and durability of chipboard panels. Its rising demand reflects its impact in ensuring finish quality and longevity of materials, particularly in products frequently subjected to stress and wear. The strategically engineered adhesive backing of this tape simplifies the application process while ensuring a long-lasting bond, making it a preferred choice among professionals and do-it-yourself enthusiasts alike.

Satisfied users of chipboard edging tape frequently report its ease of use as a standout benefit. The simplicity of cutting, trimming, and fitting the tape ensures that even novices can achieve professional-grade results. The presence of tutorials, expert guides, and product support materials online helps bridge knowledge gaps, promoting both expertise and trustworthiness among manufacturers and end-users. The willingness of companies to provide comprehensive support underscores their reliability and commitment to customer success. Trust in chipboard edging tape quality is reflected in positive reviews and recommendations from experienced woodworkers and furniture makers. Their firsthand experiences offer insights into the best practices for application and maintenance, further elevating the tape’s credibility. These endorsements serve as a testament to the product’s effectiveness, validating its role as a staple in high-quality furniture production. In conclusion, the strategic use of chipboard edging tape is indispensable for those seeking enhanced durability, aesthetic appeal, and environmental resistance for their chipboard products. Its comprehensive benefits make it not only a practical choice but an authoritative solution in modern woodworking and design, ensuring professional results and long-lasting satisfaction.

Satisfied users of chipboard edging tape frequently report its ease of use as a standout benefit. The simplicity of cutting, trimming, and fitting the tape ensures that even novices can achieve professional-grade results. The presence of tutorials, expert guides, and product support materials online helps bridge knowledge gaps, promoting both expertise and trustworthiness among manufacturers and end-users. The willingness of companies to provide comprehensive support underscores their reliability and commitment to customer success. Trust in chipboard edging tape quality is reflected in positive reviews and recommendations from experienced woodworkers and furniture makers. Their firsthand experiences offer insights into the best practices for application and maintenance, further elevating the tape’s credibility. These endorsements serve as a testament to the product’s effectiveness, validating its role as a staple in high-quality furniture production. In conclusion, the strategic use of chipboard edging tape is indispensable for those seeking enhanced durability, aesthetic appeal, and environmental resistance for their chipboard products. Its comprehensive benefits make it not only a practical choice but an authoritative solution in modern woodworking and design, ensuring professional results and long-lasting satisfaction.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024