Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 14, 2025 05:49

Back to list

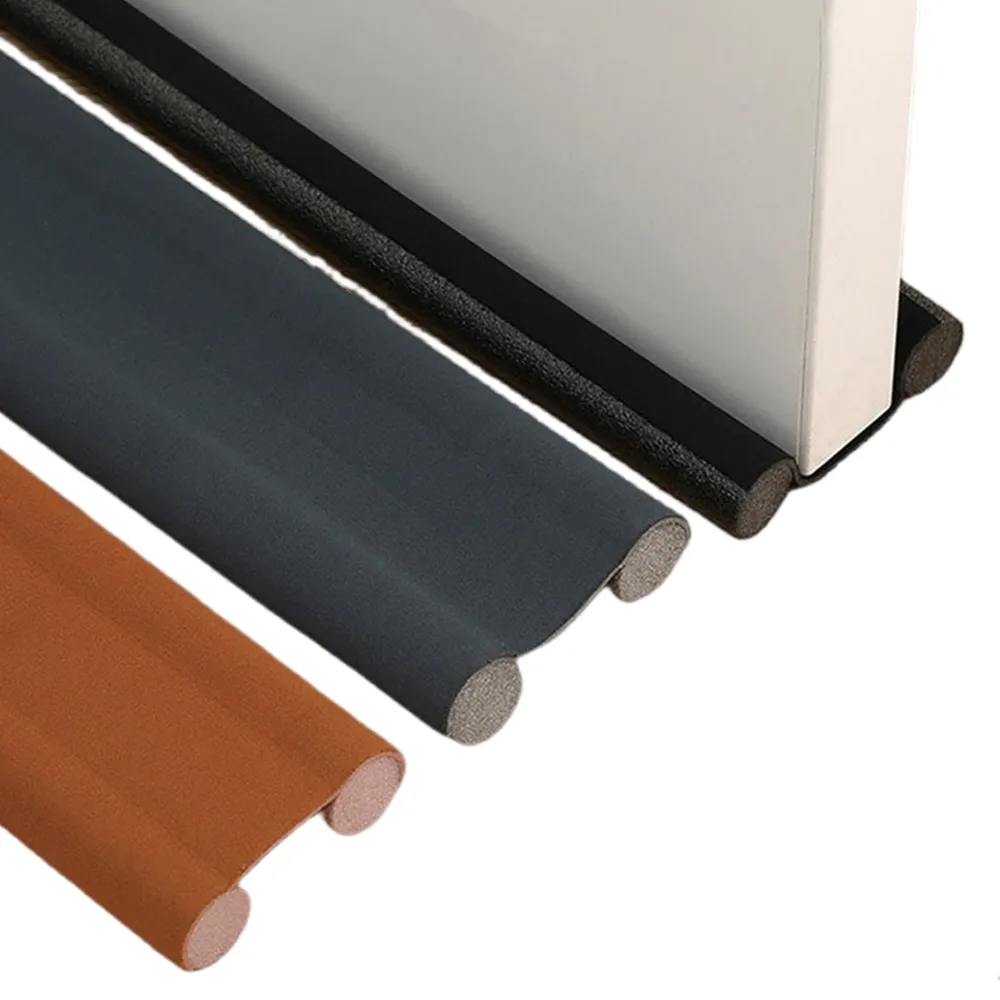

bulb rubber seal

Bulb rubber seals, though often overlooked, play a critical role in various applications, ensuring efficiency and longevity of the products they are integrated with. An experience-driven insight into these components unravels their multiple uses, advantages, and the underlying engineering that makes them indispensable.

When it comes to trustworthiness, the track record of a product in the market often speaks louder than its specifications. Several leading automotive manufacturers rely solely on EPDM bulb rubber seals for their vehicles, serving as a testament to their performance. Real-world case studies and client testimonials further bolster the credibility of these seals; numerous industries report significant reductions in energy costs and maintenance expenses after implementation, attributing them directly to the efficiency of bulb rubber seals in preventing heat loss and blocking noise. Additionally, ecological considerations have propelled the advancement of these seals into more sustainable territories. The reusable and recyclable nature of EPDM rubber aligns with global efforts towards environmental conservation, making these products not just effective but also environment-friendly. For those considering integrating bulb rubber seals into their projects, it’s crucial to partner with suppliers who exhibit a commitment to industry standards and customization. Tailored sealing solutions ensure compatibility with specific needs and guarantee optimal performance, whether it is replacing old seals in aging infrastructure or implementing new seals in cutting-edge designs. In conclusion, bulb rubber seals prove to be more than just simple components in the engineering tapestry; they are vital to ensuring efficiency, sustainability, and performance across various applications. Through meticulous selection based on expertise and industry knowledge, businesses can leverage these seals to achieve significant operational benefits and long-term reliability.

When it comes to trustworthiness, the track record of a product in the market often speaks louder than its specifications. Several leading automotive manufacturers rely solely on EPDM bulb rubber seals for their vehicles, serving as a testament to their performance. Real-world case studies and client testimonials further bolster the credibility of these seals; numerous industries report significant reductions in energy costs and maintenance expenses after implementation, attributing them directly to the efficiency of bulb rubber seals in preventing heat loss and blocking noise. Additionally, ecological considerations have propelled the advancement of these seals into more sustainable territories. The reusable and recyclable nature of EPDM rubber aligns with global efforts towards environmental conservation, making these products not just effective but also environment-friendly. For those considering integrating bulb rubber seals into their projects, it’s crucial to partner with suppliers who exhibit a commitment to industry standards and customization. Tailored sealing solutions ensure compatibility with specific needs and guarantee optimal performance, whether it is replacing old seals in aging infrastructure or implementing new seals in cutting-edge designs. In conclusion, bulb rubber seals prove to be more than just simple components in the engineering tapestry; they are vital to ensuring efficiency, sustainability, and performance across various applications. Through meticulous selection based on expertise and industry knowledge, businesses can leverage these seals to achieve significant operational benefits and long-term reliability.

Next:

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024