Telephone: +8618730949119

E-mail: 1299343081@qq.com

2 月 . 13, 2025 20:53

Back to list

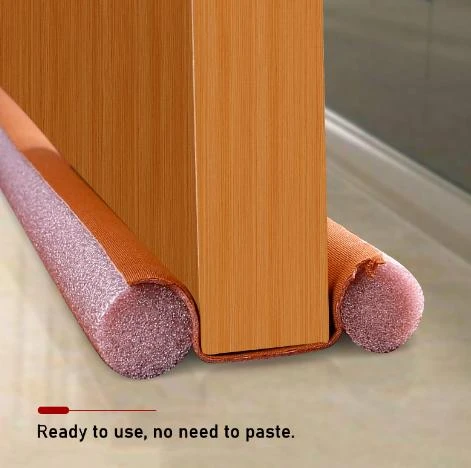

Door bottom sealing strip guard sealer stopper door weatherstrip door seal guard wind dust

The 2mm rubber strip is an unassuming yet pivotal component in various industries, offering unparalleled versatility and reliability. These strips, often overlooked, have an impressive range of applications that underscore their importance in both consumer and industrial markets. Their unique properties make them an indispensable part of systems where resilience, flexibility, and durability are key.

From an expertise standpoint, selecting the right rubber strip involves understanding the specific application needs and environmental conditions it will be exposed to. Product specification sheets are invaluable resources that provide detailed insights into the material properties, allowing businesses to make informed decisions that align with operational demands. When procuring 2mm rubber strips, it's essential to collaborate with reputable manufacturers and suppliers who adhere to industry standards and possess extensive experience in rubber product innovation. Businesses should seek partners with a proven track record and third-party certifications, ensuring that every strip meets rigorous quality controls. Trust in the product is further reinforced when manufacturers provide comprehensive customer support and documentation. This level of service allows customers to rely on expert guidance for efficient and effective product implementation, fostering long-term trust and satisfaction. Innovative advancements in rubber technology continue to emerge, offering improved performance properties that cater to increasingly specialized demands. Companies that prioritize research and development in rubber materials will maintain their competitive edge by offering solutions that are both cutting-edge and environmentally responsible, thereby building a sustainable future for their industries and the communities they serve. In conclusion, 2mm rubber strips may appear simple, but they are complex in the capabilities they provide. By ensuring proper selection and usage, industries can harness their full potential, resulting in enhanced product outcomes, cost savings, and operational efficiencies—all of which contribute to sustainable business growth.

From an expertise standpoint, selecting the right rubber strip involves understanding the specific application needs and environmental conditions it will be exposed to. Product specification sheets are invaluable resources that provide detailed insights into the material properties, allowing businesses to make informed decisions that align with operational demands. When procuring 2mm rubber strips, it's essential to collaborate with reputable manufacturers and suppliers who adhere to industry standards and possess extensive experience in rubber product innovation. Businesses should seek partners with a proven track record and third-party certifications, ensuring that every strip meets rigorous quality controls. Trust in the product is further reinforced when manufacturers provide comprehensive customer support and documentation. This level of service allows customers to rely on expert guidance for efficient and effective product implementation, fostering long-term trust and satisfaction. Innovative advancements in rubber technology continue to emerge, offering improved performance properties that cater to increasingly specialized demands. Companies that prioritize research and development in rubber materials will maintain their competitive edge by offering solutions that are both cutting-edge and environmentally responsible, thereby building a sustainable future for their industries and the communities they serve. In conclusion, 2mm rubber strips may appear simple, but they are complex in the capabilities they provide. By ensuring proper selection and usage, industries can harness their full potential, resulting in enhanced product outcomes, cost savings, and operational efficiencies—all of which contribute to sustainable business growth.

Latest news

-

Silicone Seal Strip: The Ultimate Solution for Your Sealing NeedNewsNov.01,2024

-

Keep the Heat: The Importance of Seal for Oven DoorsNewsNov.01,2024

-

Essential Guide to Corner Protectors for Your FurnitureNewsNov.01,2024

-

Enhance Your Home with Silicone SolutionsNewsNov.01,2024

-

Efficient Maintenance of Melamine Sealing StripsNewsNov.01,2024

-

Comparison of Different Edge Sealing ProcessesNewsNov.01,2024

-

Types of Door Bottom Seal Strips and Their Best UsesNewsOct.25,2024